In organic fertilizer making process, moisture content usually plays an important role. Both too much and too little water will affect the quality of organic fertilizer production. Especially in processes of composting, granulation and bagging. Then what moisture content is required in the organic fertilizer making process? YUSHUNXIN offer right answer here.

Ideal moisture content for better organic fertilizer composting

How reduce moisture content before organic fertilizer composting

The standard for final organic fertilizer before packaging

Is it the end? No. Finally, you must adjust the moisture content of final organic fertilizer to below 10% before packaging. There are two reasons.

How to regulate fertilizer moisture before packaging

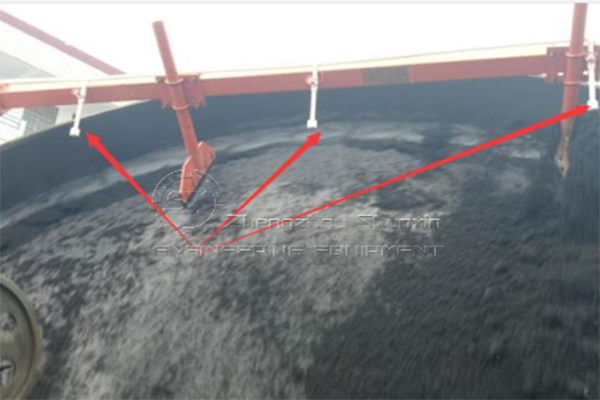

Here, if you want to dry fertilizer quickly and easily, it is advisable to use rotary drying machine, which plays an important role in fertilizer drying. During working, the hot air in the SX drum dryer can reach 300 ℃. Therefore, this machine can reduce your organic fertilizer to below 10% in a short time.

Besides, we also can offer you many other solutions for organic fertilizer making. Such as organic compost order removing, composting time, organic fertilizer granulation rate, etc. There are customized fertilizer business plans for you!