Dust generation is a common challenge in fertilizer manufacturing, especially during material handling, granulation, and drying processes. Excessive dust not only affects the working environment and health of employees but can also lead to fertilizer machinery wear and material waste. Therefore, effective dust control is crucial in any fertilizer making plant. Then, how to control dust generation in fertilizer making? How about the effect? All answer is here.

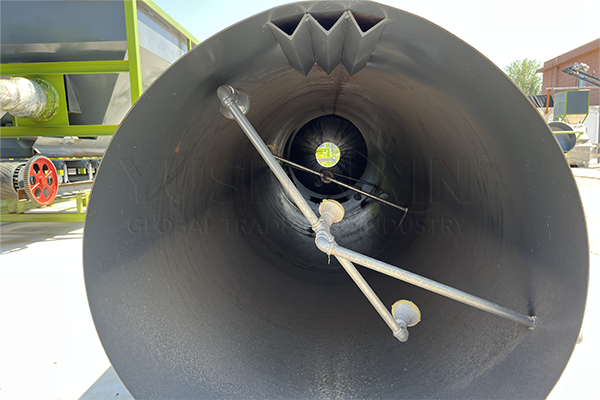

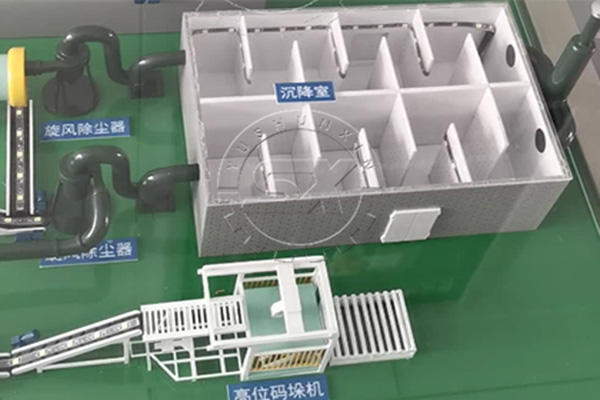

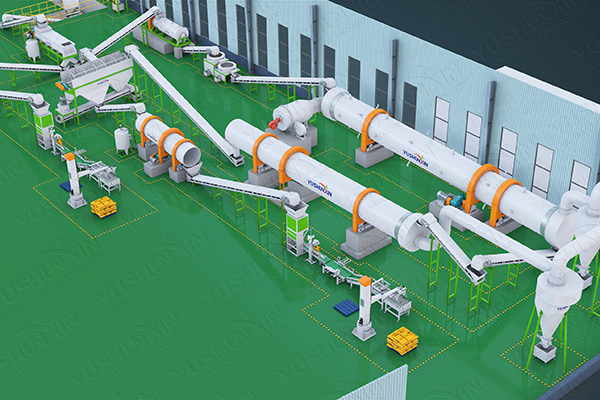

Solution 1: Professional dust collectors after fertilizer drying

The professional dust collecting system is the most effective step to control dust generation in fertilizer making. Commonly, the system contains cyclone dust collectors, water curtain dust collectors, and dusting fall rooms.

Solution 2: Add dust cover to control dust generation for material transport and screening

During fertilizer production process, you also can reduce the dust generation in material transport and screening. Installing dust covers on belt conveyors and fertilizer screeners is a simple yet highly effective method to control dust from escaping into the surrounding environment.

Solution 3: Dust reduction for fertilizer granules manufacturing

If you want to produce fertilizer granules, there are also some tips for you.

how about the dust reduction effect for a fertilizer making plant?

Generally, the dust collector system should be adequate to ensure the dust level ( SPM = suspended particulate matter) inside the plant should be less than 50 mg/m3 .

If you want to know more about fertilizer making, whether it is organic fertilizer production or chemical fertilizer manufacturing, welcome to contact us now! YUSHUNXIN will offer you the best solutions.