Is there a business plan for large scale organic fertilizer manufacturing? Of course. We can provide you with 100,000 t/y organic fertilizer production project. And in terms of hourly output, it can reach 15-20 t/h. So it can fully meet your requirement of commercial organic fertilizer making in large quantities. In addition, according to the needs of different fertilizer manufacturers, we especially design various 100,000 t/y organic fertilizer preparation systems. Such as 100,000 t/y organic waste composting system, 100,000 t/y compost granulation line, 100,000 t/y organic fertilizer packaging system, etc. If you have any other requirements, you can contact us immediately, we will offer you the best fertilizer making solutions.

How to start 100,000 t/y organic compost fertilizer production project?

If you want to turn organic waste (cow dung, chicken manure, mushroom waste, etc) into compost in a large scale, you can choose our 100,000 t/y large scale composting line. In this process, you need to take three steps:

What equipment is used in large scale compost granulation?

Is there fertilizer making plan for further process manure compost? The answer is yes. If you have completed the composting of organic waste, you can purchase 100,000 t/y compost granulation line directly. During 100,000 t/y compost pellets making, you may need equipment: rotary drum granulator, screener, dryer and cooler.

100,000 t/y packaging system for your finished organic fertilizer processing

When you have finished organic fertilizer making and want to sell to your customers, it is advisable to use our packaging system for large scale organic fertilizer manufacturing. Because in this system,

How to reduce the dust pollution in the 100,000 t/y organic fertilizer production project?

For large scale 100,000 t/y organic fertilizer production project, there is an item you also must pay attention to. It is purifying waste gas discharged from organic fertilizer preparation. For this, our engineers have three advice for you.

- 1

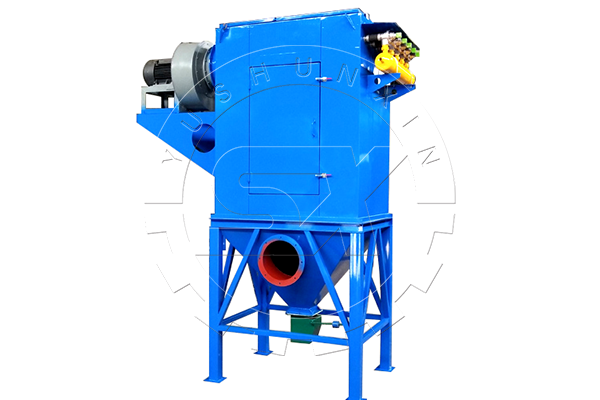

Buying professional dust collector

We can provide you with cyclone dust collector, water curtain dust collector and bag filter dust collector. They are commonly used to collect dust caused by fan in the drying and cooling process of organic fertilizer preparation.

- 2

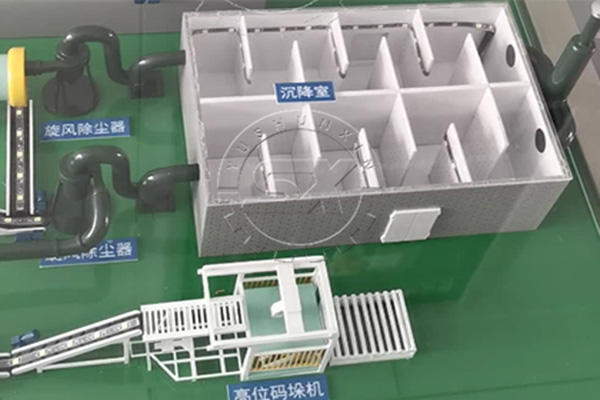

Building dust fall room

Besides professional dust collectors, you also can filter exhaust gas of drying by building a dust fall room. There are a number of vertical baffles in the dust fall room. When the gas flows through, it will change direction and reduce speed, and the contained dust particles will collide with the baffle and fall.

- 3

Adding dust cover

But how to prevent dust pollution in other processes of 100,000 t/y organic fertilizer manufacturing? You can add dust cover to large scale organic fertilizer equipment. For example, installing dust covers on rotary screener, belt conveyors, etc.

Technology parameters of equipment can be used in 100,000 t/y organic fertilizer production

| Equipment | Model | Capacity (T/H) | Power (KW) | Dimension (MM) | Quantity |

|---|---|---|---|---|---|

| Wheel type compost turner | 1 | ||||

| New type vertical crusher | SXLFL-1000 | 8-15 | 37 | 2150*1220*2700 | 2 |

| Rotary drum granulator | SXZGZ-3210 | 15-30 | 37 | 10000*3200*3200 | 1-2 |

| Rotary screening machine | SXGS-2080 | 10-20 | 11 | 1 | |

| Rotary drying machine | SXHG-2424 | 14-18 | 1-2 | ||

| Rotary cooling equipment | SXLQ-2424 | 14-18 | 1 | ||

| Rotary coating equipment | BM1800×8000 | 15-30 | 11 | 6000*1600*1600 | 1 |

| Dynamic batching machine | 1 | ||||

| Automatic packaging scale | 1 | ||||

| Automatic palletizer | SXMD-800 | 500(bag/h) | 4 | 3200*2200*3000 | 1 |

| Dust collector | 1 | ||||

| Belt conveyor | 1 |

How much does the large scale organic fertilizer manufacturing line cost?

Finally, the mass production of organic fertilizer cost is an item you must consider. Because of large capacity, high erosion resistence, better fertilizer granule making effect, the organic fertilizer manufacturing line investment need more . About $300,000-$500,000. The precise quote is depended on the every fertilizer equipment material, design, etc. You can send us your budget details now, we can design customized organic fertilizer business plan for you!

In addition, we also can offer you many other organic fertilizer making lines. Such as 50,000 tons/ year organic fertilizer making plan, 20,000 TPY organic fertilizer granulation systems, bio organic fertilizer manufacturing line, etc. Welcome to contact us immdiately to get your own fertilizer making line.