When you plan to dispose of the manure from your small farm and make it into organic fertilizer, there is an item you must focus on. Removing harmful substances from manure and eliminating its odor. In this respect, aerobic fermentation is the most commonly used method for fertilizer manufactures. Then in the presence of oxygen, how many types of methods can we use in small scale composting of manure? In general, there are three types of small scale composting methods for your choice. Including groove composting, windrow composting and in-vessel composting. They differ in terms of equipment model, capacity, area occupation, fermentation time, cost, etc. You can choose the most suitable one according to your needs.

What you need to learn when you want to start small scale groove type composting of organic waste?

Are you finding a small scale cow manure composting system with a high degree of automation? If you are, you can choose groove type composting. We equip all types of small scale groove composting machines with electrically automatic control systems. So after setting in motion, they will move along the rails on the two sides of fermentation grooves and turn materials to facilitate cow dung composting without worker operations. However, if you want to know whether it is suitable for your small scale manure compost making, you also need to learn the performance of it in the following aspect:

Equipment types

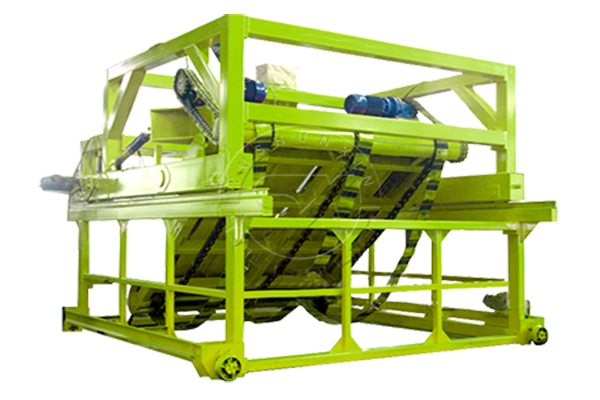

In SX, there are usually two types of small scale groove type composters for your choice. Groove type compost turner and chain plate type compost machine. The former is typical equipment for starting manure composting in fermentation trenches. It mainly relies on stirring teeth on the shaft to process compost. But the latter, in order to speed up aerobic fermentation of organic litter, replaces the turning part with chain plate type part, which makes material more fully contact with oxygen.

Under natural conditions, organic fertilizer composting will take you 2-3 months. But our equipment for groove composting can help you finish small scale fermentation of organic manure within 20 days.

During groove composting, the area occupation is determined by the scale of composting. The smaller the fermentation scale, the less area occupation; the larger the fermentation scale, the more the area occupation.

| Equipment | Turning Width (mm) | Turning Depth (mm) | Power (kw) | Cost ($) |

|---|---|---|---|---|

| Groove Type Compost Turner | 2500-5000 | 800-1500 | 15-18.5*2 | 3000-8000 |

| Chain Plate Type Compostor | 4000-5000 | 1600-2000 | 22*2 | 5000-12000 |

5 Things you must know about small scale windrow composting

If you want to start small scale fertilizer composting without fermentation trenches building, we recommend you adopt windrow composting, which is also known as on the ground fermentation mode. In this process, you only need to pile organic manure into long windrows and drive windrow compost machine to turn and mix windrows. When the temperature of materials on longer rises, you can get finished compost fertilizer. And in order to help you learn this type of small scale composting method, we summarize the 5 things that fertilizer manufacturers are most interested in about small scale windrow fertilizer fermentation.

| Equipment | Turning Width (mm) | Turning Depth (mm) | Capacity (m³/h) | Cost ($) |

|---|---|---|---|---|

| Crawler Type Compost Turner | 2400-3000 | 600-1500 | 500-1500 | 5000-20000 |

| Moving Type Compost Machine | 2000 | 600-800 | 400-500 | 3000-6000 |

Details of in-vessel organic manure composting in small quantities

Is there a method which can turn organic waste into compost fertilizer in small quantities faster? Which type of small scale composting needs a smaller area? For this, in-vessel fermentation is an ideal choice for you. The details of in-vessel small scale composting is as follows:

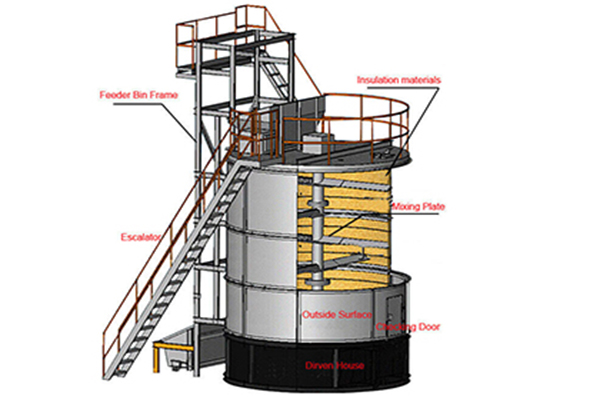

Types of small scale in-vessel fermentation tank

At present, we have two types of small scale composting in-vessel fermentation pots on sale. One is horizontal organic fertilizer fermentation tank and vertical fermentation pot. They are both full automatic fertilizer composting machines. Controlled by computer, and it has automatic temperature and oxygen content monitors. Therefore, using it, you can convert organic litter to compost fertilizer quickly and easily.

Output of in-vessel composting machine

If you need an in-vessel composter with a capacity below 50 ㎡, we recommend you purchase horizontal fertilizer fermentation tank. However, when your expectant output is higher than 50 ㎡, it is advisable to buy vertical fermentation pot for your small scale organic fertilizer composting.

What’s more, only needs a small space, it can complete the whole small scale composting process. Even it is an area of 10-30 ㎡.

In addition, whether you want to further making compost into organic fertilizer granules or enlarge the fertilizer fermentation scale, we can offer you the best solutions. It is designed according to your busget, material, area, etc.