With the increasing demand for chicken meat, most chicken farms gradually convert to intensive breeding. So the management of chicken poop has increased significantly, and the traditional chicken waste disposal system is no longer applicable. Here, you can replace it with the system of making chicken manure into organic fertilizer, which is an commercial and environmentally friendly solution. Here, you can choose to process chook poop into granular, powder and liquid fertilizers freely. If you want to get your own chicken waste disposal plan, welcome to contact us immediately.

Top 1 commercial chicken manure management – Granular organic fertilizer production line

If you want to make more profits while improving the chicken waste disposal system, you can choose to prepare chicken dung into fertilizer pellets. After making chicken manure into granules, it is not easy to stick to each other and has a low possibility of nutrients layering during transport and storage. What’s more, granular broiler manure fertilizer can supply nutrients to the growth of crops and plants better. So there are so many fertilizer suppliers who choose to dispose of chicken litter into granules. And from our customer feedback, there are two chicken manure granulation lines that are hot selling.

What is the design of chicken manure disc fertilizer granulation line?

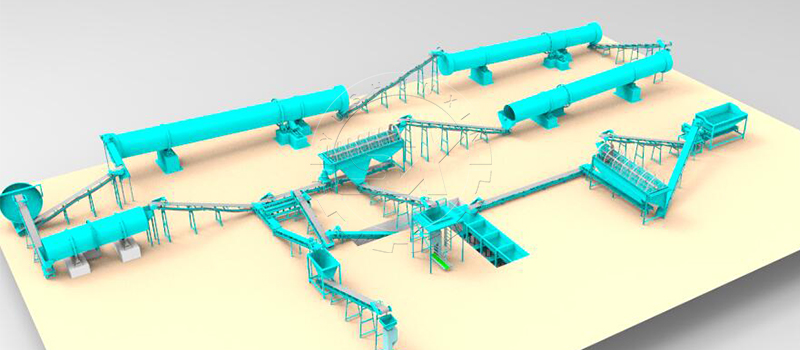

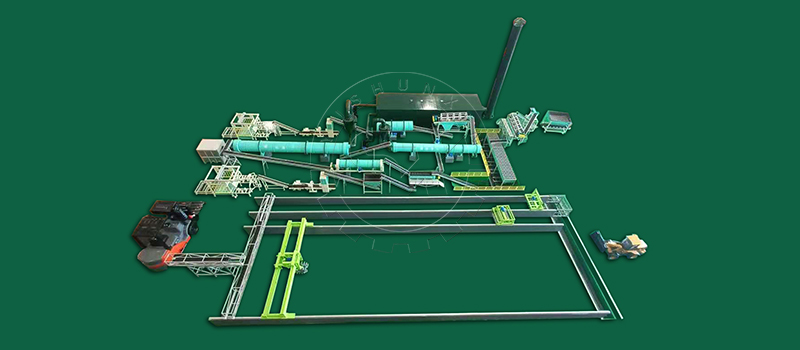

In general, a complete 6 t/h pan fertilizer pellet making system contains windrow type compost machine, static batching machine, SXSF-120 semi-wet material crusher, double shafts horizontal mixer, SXYZ-3600 disc granulator, SXGS-1240 rotary screener, SXHG-1515 rotary dryer, SXLQ-1515 rotary cooler, BM1400×4000 coating machine, automatic bagging machine and so on. Moreover, if you want to buy it for your chicken waste disposal, you only need to prepare about 45,000 ㎡ of installation site and $190,000.

Chook dung large rotary drum granulation line configuration

In this chicken poop processing plan (taking 15 t/h capacity as an example), you need to use wheel type compost turner, dynamic batching machine, SXSLF-1000 new type vertical crusher, SXWJ-1630 horizontal mixer, SXZYZ-2080 rotary drum pelletizer, SXGS-2080 rotary screener, SXHG-2424 rotary dryer, SXLQ-2424 rotary cooler, BM1600×6000 coating machine, automatic packaging equipment and so on. And it usually needs an area of 5,500-10,000 ㎡ to turn chicken manure into organic fertilizer granules. And the price of it is about $360,000-550,000.

The above organic fertilizer production lines are not only suitable for chicken manure disposal, but also for cow dung management, pig manure treatment, goat poop recycling, etc. In addition, if you have any other requirements for the chicken manure disposal system, you can contact us for your customized design.

Is there an more economical chicken waste fertilizer manufacturing plan?

If you dispose of your chicken farm manure in an economical way, we recommend you make it into powder fertilizer. It can fully meet your requirements, whether you plan to start small organic fertilizer production or large scale organic fertilizer manufacturing. Usually, a complete powder fertilizer production line only costs $3,500-$90,000.

Small scale chicken manure disposal

Large scale chicken dung management

Low cost chicken dung treatment

Why does powder chicken manure fertilizer production line have such a favorable price?

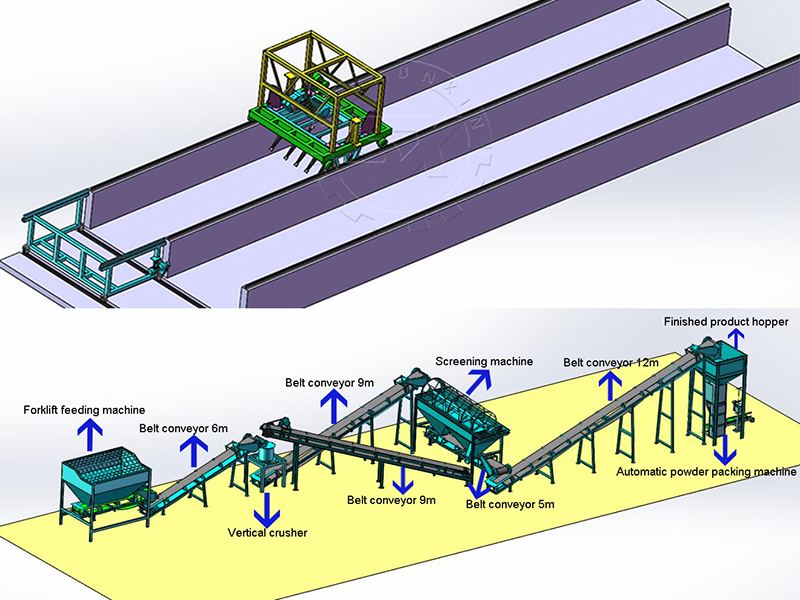

Simple equipment configuration

In general, the whole powder chicken dung fertilizer manufacturing consists of compost machine, loader type feeder, crusher, powder screening machine, powder packaging equipment. Only 5 types of organic fertilizer processing machines, it is far fewer than that of other chicken manure fertilizer production systems. The less equipment used, the lower the cost of producing organic fertilizer from chicken manure. Therefore, this chicken manure treatment system can greatly reduce your cost of equipment purchasing.

High degree of automation

In addition, it also makes you spend less on worker employment for chicken dung disposal. Because powder fertilizer production line is equipped with an electrical control system, which greatly improves automation. Even it can provide you with a fully automatic chook dung fertilizer production system. So only need to employ 2-5 workers, you can process chicken waste into quality organic fertilizer.

Less occupation

Finally, buying system of making chicken litter into powder fertilizer also has a characteristic of less area occupation. The smallest powder chicken waste fertilizer preparation line only covers an area of 800 ㎡. So it can help you decrease the cost of workshop rent. And you can even process chicken manure into fertilizer directly on your farm.

Can I make chicken manure into liquid fertilizer?

Of course. There are various stainless steel liquid fertilizer making machines for you. Including solid-liquid separator, filters, liquid fertilizer reactor, UV sterilization equipment and liquid filling machine, etc. They can help you turn fresh chicken manure into liquid organic fertilizer quickly.

How to buy quality equipment for your chicken dung fertilizer making system?

After deciding your chicken waste disposal plan and equipment, you also need to pay attention to quality chicken dung fertilizer making equipment purchasing. High quality fertilizer machines have characteristics of high working efficiency, less impediment, less maintenance cost, etc. But how to buy quality chicken waste fertilizer processing equipment? There are three tips for you.

Inquire those who have started chicken waste disposal

Usually, it takes time and lots of effort to find the best chicken manure fertilizer preparation machines on the market. Luckily, some people have been using these machines for several years. They have used machines from different manufacturers. So, they know the best chicken poop disposal machines on the market. If you can get recommendations from these people, you can save more time and money. They can even stop you from choosing the wrong machines.

Choose a reliable fertilizer equipment manufacturer

A leading, reliable and experienced manufacturer more likely to produce high-quality chicken manure processing machines. Such as YUSHUNXIN. As a reputable fertilizer equipment manufacturer, we have more than 20 years of experience in chicken waste machine production. We hire skilled and experienced workers to design and produce different types of machines. In addition, we also can help you pick the right machine for your broiler litter making business and offer you great discounts.

Can we make granular / power/ liquid fertilizer from other organic waste? The answer is yes. As a professional fertilizer bussiness provider, there are also many other organic waste fertilizer systems for you. Such as cow dung to fertilizer plan, pig manure fertilizer making method, etc. If you have any other requirements, welcome to contact us for your own fertilizer production line now!