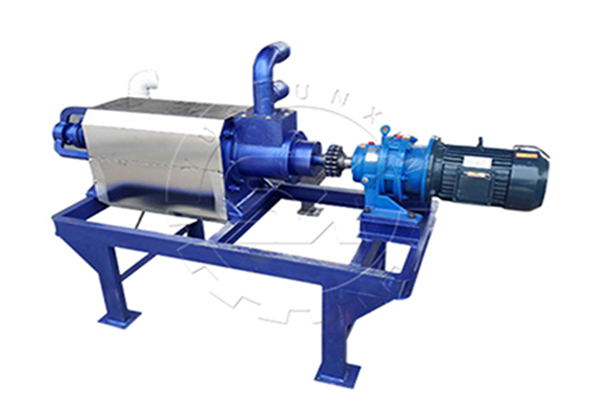

Manure dewatering machine is a key fertilizer processing equipment of manure drying system. It can adjust the moisture content of manure to a proper level, so that you can compost organic fertilizer quickly and easily. And in order to fully meet your requirements, we especially design many types of manure dehydrators according to different manure materials, capacity, etc for your choice. Besides, even if you want to further process dehydrated manure into organic fertilizer, we also can design business plans according to your actual conditions.

Why we need to use manure dewatering machine in organic fertilizer production?

Animal manure is the most common material for organic fertilizer manufacturing, because it contains rich nutrients which are beneficial for the growth of crops and plants. But when you use fresh manure as fertilizer, it is necessary to remove excessive water from manure. Why? In general, there are two reasons as follows:

Making manure suitable for organic fertilizer composting

The reason why we cannot use animal manure as fertilizer directly is that it contains many pathogens, pest eggs and grass seeds. They are harmful to the soil and will affect the healthy growth of crops. So you need to compost manure before preparing organic fertilizer. In this process, it is essential to control the moisture content of manure between 40% and 60%. Which can meet the needs of water supply for aerobic fermentation and will not block the transport of oxygen.

Making manure easy to transport

In addition, fresh manure is a mixture of liquid and solids, so it is not convenient to transport to composting area or to disposal center. Especially cow dung, pig manure, etc. After processing with manure dehydrator, the solid animal manure will be separated from liquid and its moisture content can be reduced to 30%-40%. Only by driving forklifts can you transport manure to fertilizer composting area quickly and easily.

What kind of material can manure dehydrator machine process?

For organic fertilizer making, there are various materials for your choice. For animal manure, you can use chicken manure, pig litter, cow dung, etc. Can manure dewatering machine process all of them? Of course. We can provide you with the most suitable manure solid-liquid separator according to your material.

| Equipment | Model | Capacity (m³/h) | Power (kw) | Diemensions (mm) | Feed Moisture |

|---|---|---|---|---|---|

| Screw Type Dehydrator | SXTS-180 | 10-15 | 4 | 1850x650x1150 | 50%-70% |

| Equipment | Model | Capacity (m³/h) | Power (kw) | Diemensions (mm) | Feed Moisture |

|---|---|---|---|---|---|

| Inclined-screen Dehydrator | SXTSX-800 | 15-20 | 4 | 1700x1500x1300 | >80% |

| Equipment | Model | Capacity (m³/h) | Power (kw) | Diemensions (mm) | Feed Moisture |

|---|---|---|---|---|---|

| Screw Type Dehydrator | SXTS-230 | 15-20 | 5.5 | 1700x1500x1300 | 50%-70% |

| Inclined-screen Dehydrator | SXTSX-1200 | 30-40 | 5.5 | 2200x1500x1700 | >80% |

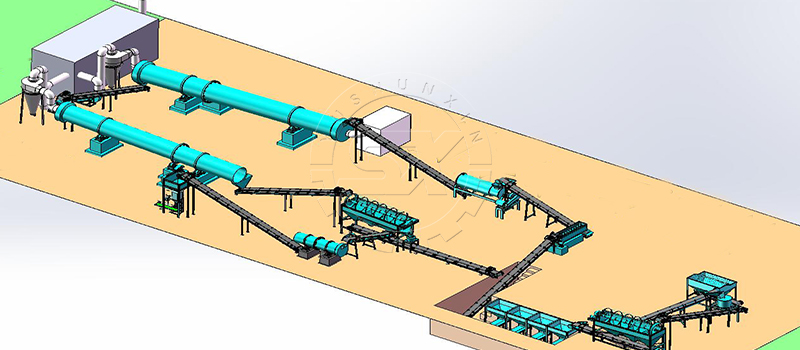

Is there solid liquid separator for dewatering manure over 50 m³ per hour?

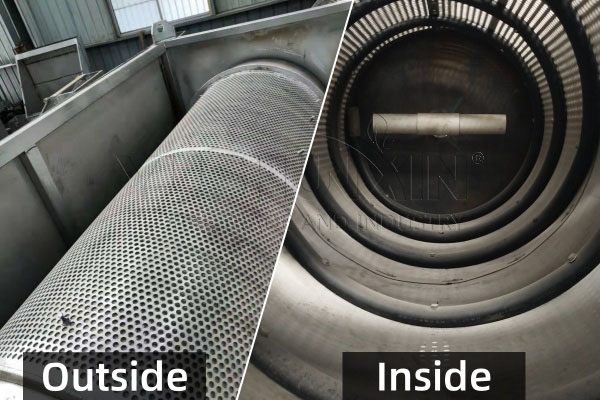

Of course. YUSHUNXIN especially design rotary drum dewatering equipment for larger scale manure disposal or large organic fertilizer making. For one thing, the drum design can accomodate more material. For another, it also can reduce the moisture of manure waste quickly, because the machine also adopts solid liquid separation + pressing method.

Drum manure degydrator working process

When manure waste enters the rotating drum through the feed inlet, gravity and centrifugal force work together to facilitate liquid and solid manure waste separation. The solid particles, being larger than the screen openings, are retained inside the drum and gradually move toward the discharge end as the drum rotates. Meanwhile, liquid and fine particles pass through the screen and collect in a liquid reservoir below, completing the initial solid-liquid separation process. Finally, there is screw type dehydrators for further drying of manure waste.

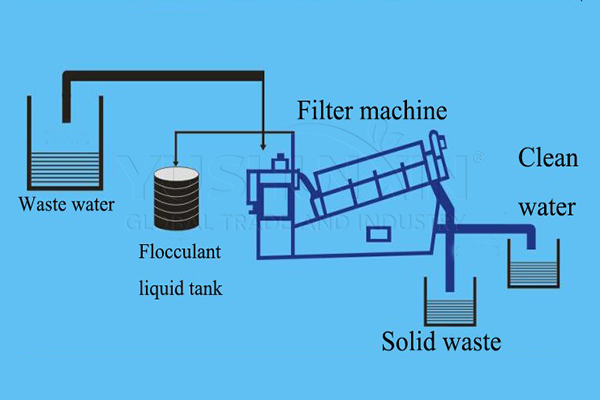

How to dispose of manure waste in more environmental way?

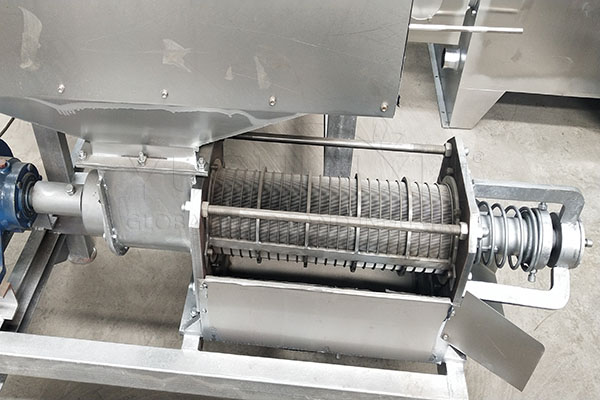

For thoese who are in a country where requires a better manure liquid disposal, you can buy a stacked screw dehydrator. It can separate smaller particles from the liquid. Ingeneral, it contains 4 parts.

This method ensures thorough separation of solid and liquid manure, making it easier to process the solids into compost, fertilizer, or biofuel, and safely handle the liquid for use in irrigation or other applications.

How does solid-liquid separator work to remove excessive water from manure?

Turn on manure dewatering machine

Our manure dewatering machine has an electrical control system, which makes itself easy to operate. This will makes you freely start and stop the host and pump. Therefore, only by employing one worker can it complete the whole manure dehydration process.

Feed manure materials

After set in motion, the pump will work to transport raw materials to the dehydrator. Here, we especially design inlet and overflow outlet for feeding manure materials into dehydrator more smoothly.

Dewatering

After feeding, it will start removing excessive water from manure. But as mentioned above, there are two types of manure dewatering machines, and they are different in dewatering methods. Screw type dehydrator only makes use of screw rotation part and sieve to extrude feeding manure. However, when it comes to inclined screen solid-liquid separator. It will separate solid manure from the liquid before starting extrusion.

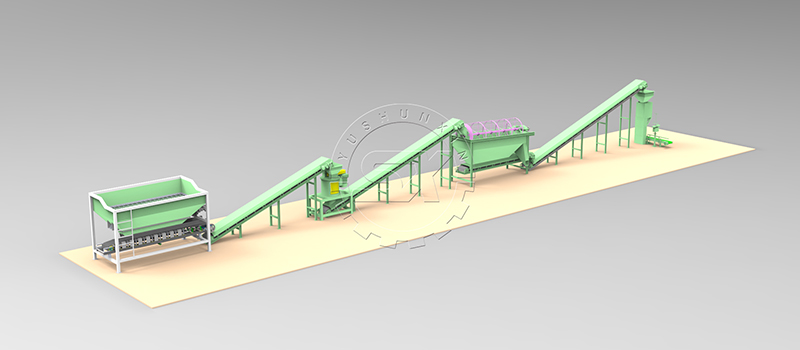

How to further process dehydrated manure into organic fertilizer?

After dewatering, can manure be used as organic fertilizer directly? The answer is no. You need to further process it into compost. Because it still contains many pathogens, parasite eggs and grass seeds, which are harmful for the soil and not suitable for quality manure fertilizer production.Then, after manure composting, there are two choices for you.

Is there other machines for manure fertilizer making? Of course. Because manure dehydrator, YUSHUNXIN also can offer you composting machine, manure pellet machine, fertilizer packing equipment, etc all sets equipment for organic and compound fertilizer making. Welcome to contact us for your customized fertilizer business plan now.