What you need to consider when start organic fertilizer composting or buy compost machine? Moisture content? Temperature? Capacity? Budget? All factors are considered when YUSHUNXIN designs windrow composting facility, which piles materials into long windrows on the flat ground to make compost fertilizer. It can keep the temperature and moisture content of raw material at a proper level for better fertilizer fermentation. In addition, we design different types of windrow compost turners according to your capacity and budget. Therefore, are you still looking suitable compost equipment for your organic waste fertilizer making? YUSHUNXIN windrow composting equipment is your best choice!

How does windrow composting facility design work to speed up organic fertilizer composting?

For the aerobic fermentation of organic manure, it is essential to control the temperature and water content. Why? Because high temperature is the secret of killing pathogens, parasite eggs and grass seeds in manure. Moreover, water is the basis of microorganisms activities, which can decompose organic matter and generate heat. Then how to adjust the temperature and water content for organic fertilizer composting? Windrow composting machine has its unique designs.

Control temperature of manure fermentation

What is the best temperature for fast manure composting? In general, it is 60℃-70℃. Because as long as the temperature rises to 60℃, the harmful substances in manure can be killed. But when it is higher than 70℃, the beneficial bacteria will also die. Then what is the best way to regulate the temperature? It is windrow turning machine, which has stirring teeth with 2200-2400 r/min. So it can mix and turn windrows to supply oxygen to support hot composting and enhance porosity to dissipate excessive heat.

Adjust moisture content for better composting

Another way to speed up organic fertilizer composting is to keep material moisture between 40% and 60%. Since when the moisture of windrow is lower than 40%, the activity of microorganism will be inhibited. And the reason why the water content cannot rise to 60% is that it will decrease porosity. This will affect both oxygen transport and heat dissipation. But you will find that even you adjust moisture to a suitable level before composting, it will decrease continuously because high temperature. Windrow composting machine can solve it perfectly. It can be equipped with a water spraying system, including piping, nozzles and pump, to facilitate the addition of water to materials while compost turning.

What is the capacity of windrow compost machines?

Capacity always plays an important role in composting turners selection. In order to meet the requirements of different fertilizer manufacturers, we design various windrow compost facilities for your choice. You can buy the right one whether it is to produce compost fertilizer in a small or large scale. The range can reach to 500 m³/h to 1500 m³/h.

How to start small scale windrow composting?

For small scale organic fertilizer composting, most fertilizer suppliers will choose our moving type self-propelled composter. For one thing, it can process windrows with a width of 2 m and a height of 0.6-0.8 m. So it can treat 400-500 m³ of organic material per hour, which is suitable for preparing compost in a small scale. For another, it adopts a four-wheel moving system, which makes it move forward, backward and turn direction freely. In this way, you can reduce the cost of fermentation groove building and transfer vehicle buying. Therefore, it is an ideal choice for those who want to purchase a cost-effective windrow composting facility.

Is there a windrow composting facility that can process 1,000 m³ of manure per hour?

Of course. SXLDF-2600 hydraulic crawler type compost turner is prepared for you. It is capable of working with base heaps with a width of 2.6 m and a height of 1-1.3 m . That is, the capacity of this hydraulic windrow compost machine can reach 1,000-1,200 m³/h. Moreover, in order to improve its composting efficiency, we upgrade the moving system and control system. Its moving system adopts crawler type, which has a higher adaptability for the ground and makes the machine work more stable. At same time, we equip it double control rods system, which is more suitable for operating crawler type moving system. So it can help you finish large scale composting quickly and easily. In addition, we replace the open operation system with driving cab, which can isolate odor and material splash to provide better working conditions for workers.

What is the maximum output of windrow compost machine?

The maximum capacity windrow composting equipment in YUSHUNXIN is SXLDF-3000. Its composting span is 3 m and its turning depth is 1.3-1.5 m. This is the reason why it can compost 1,300-1,500 m³ of organic fertilizer per hour. But compared with its large capacity, its energy consumption is low. The power of SXLDF-3000 crawler type windrow compost turner is 156 hp.

Can we turn fertilizer compost windrows of 1500 m³/h more economically?

The answer is yes. There is towed windrow compost turner which is drived by tractor. With 2.5 m turning width and 0.8 m turning depth, it can help you processing 800-1500 m³ of organic compost piles per hour easily. But, for the investment, you only need to preapre $4,ooo-$8,000. Therefore, the windrow compost facility is an economical choice for those who has tractor in your farms already.

How much do compost windrow turners cost?

As a professional fertilizer equipment manufacturer, we can provide you with fertilizer making plans according to your budget. It is the same as windrow composting. In terms of price, we can offer you windrow composting machines with costs of $6,000-$12,000 and $10,000-$70,000.

Can semi-skilled workers operate the windrow compost facility?

What can I do after windrow composting?

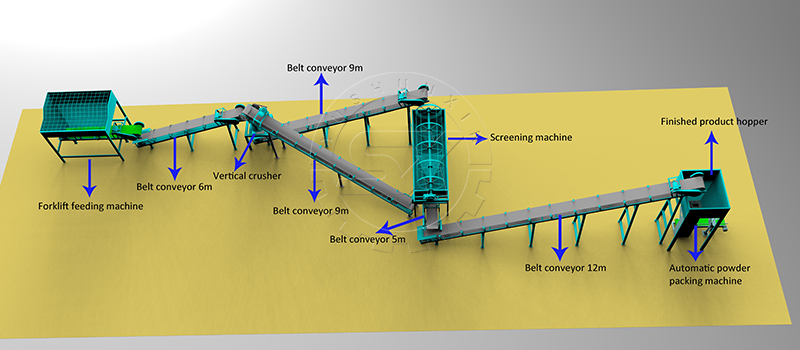

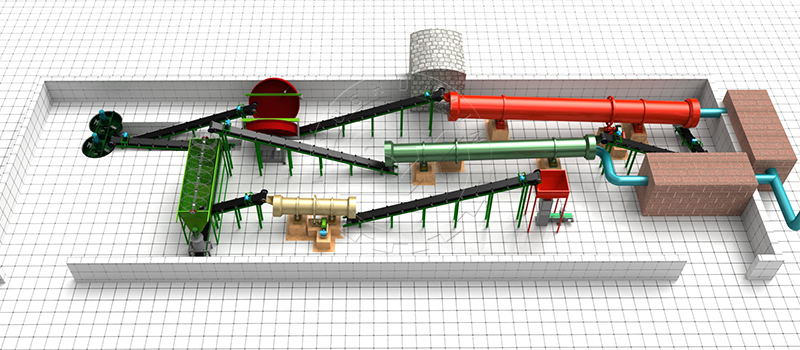

After finishing windrow composting of organic waste, you can further process it into organic fertilizer. YUSHUNXIN can provide you with business plans according to your actual conditions. For example, compost powder organic fertilizer making plan, compost granulation line, etc.

If you have any other thing want to know about windrow composting facility or inquiry other compost equipment, come to contact us now! There are in-vessel compostor for fast fermentation, wheel type compost turner for large scale organic manure decomposition, etc.