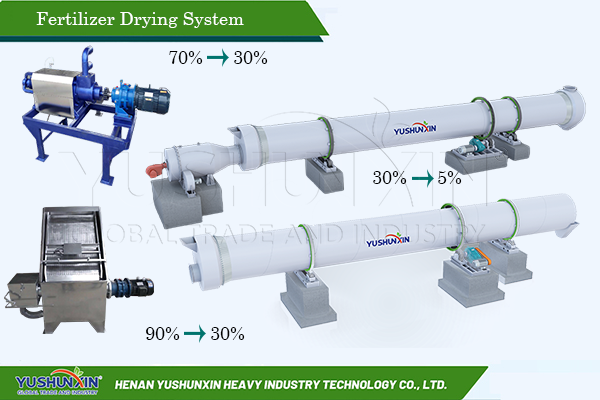

Animal manure is the most commonly used material in organic fertilizer production. But fresh animal manure usually has a high moisture content between 70%-90%, which is not suitable for organic fertilizer manufacturing. Therefore, it is necessary to dry the manure, and it runs through the whole process of organic fertilizer making. For this, we especially design a manure drying system for you. It can fully meet your requirements of drying manure fertilizer before composting and after granulation. They generally play important roles in organic fertilizer making. So manure drying manure is greatly helpful for you to turn animal manure into quality organic fertilizer.

Dewatering machine of manure drying system

Rotary drying machine of manure drying system

When need to dry manure during the organic fertilizer production process?

Generally speaking, moisture control is essential in the whole process of organic fertilizer preparation with manure. However, in fact, you only need to dry manure at the beginning and the end steps. They are before composting and after granulation. Why? And what are the moisture requirements in these two steps?

Before organic fertilizer composting

Composting usually plays an important role in organic fertilizer production, because it is a process of eliminating harmful substances in manure. In this process, it is necessary to control the moisture content at 40%-60%. Because when the water content of manure is higher than 60%, excessive water will affect the transport of oxygen and reduce the composting effect of manure. When the moisture content is lower than 40%, microorganism activity will decrease. So it cannot generate enough heat to kill harmful substances in animal manure. In general, the water content of fresh manure is 70%-90%, which is far higher than 60%. So before composting, you need to dry manure first.

After organic manure granulation

Then it is indispensable to adjust the moisture content at the end of making granular organic fertilizer from manure. That is, before packaging and after granulation. It is advisable to reduce the water content of manure fertilizer to lower than 10%. In this way, your final manure fertilizer can be stored for a longer time. But after granulation, the water content of manure fertilizer is 15%-20%. Therefore, you need to dry manure fertilizer again.

What equipment is needed in the manure drying system?

Generally, the drying system in manure fertilizer manufacturing contains 2 parts. Manure dewatering before fertilizer composting and manure fertilizer hot air drying after granulation.

Manure dewatering before composting

How to dry manure before fertilizer composting? Commonly, there are two ways for your choice. On the one hand, you can add materials with low moisture content to animal manure. Such as straw, sawdust, corn cobs, etc. But if you want to dewater manure faster and easier, we recommend you use manure dehydrator directly. And usually, there are two types of manure solid-liquid separators for your choice.

Manure drying machines after granulation

Besides equipment for drying manure before composting, we also can offer you quality drying equipment for reduce the excessive water from manure after granulation.

Rotary drying machine

What equipment can be used in the manure drying system after granulation? In this process, rotary drum dryer is your best option, especially pan granulation and rotary drum pelleting. Compared with dewatering equipment, it relies on high temperature to process manure. The temperature in drying drum can reach 300℃, so rotary drying machine can further reduce the moisture content of manure fertilizer pellets to a lower level, about 10%.

Rotary cooling equipment

Can we directly package manure fertilizer after rotary drum drying? No, we cannot. After rotary drying of animal manure, the temperature of final organic fertilizer is about 30℃ – 40℃. Which will affect the quality of your manure organic fertilizer and is not suitable for bagging and storing directly. So there is rotary cooling machine designed for you. It can reduce the excessive temperature of manure fertilizer quickly.

What is the cost of a manure drying system?

If you need other machines for fertilizers processing, YHUSHUNXIN also can fully meet your requirements. Such as composting machine, granulators, crushers, mixer,packaging equipment, etc. Welcome to tell us all you requirements for fertilizer manufacturing now!