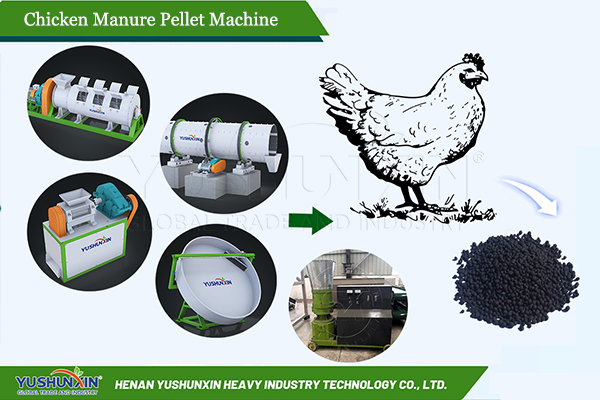

In the process of chicken manure fertilizer making, many fertilizer manufacturers prefer to make chicken poop into pellets. Because granular chicken manure fertilizer is more convenient to transport, store and use. But how to produce quality organic fertilizer pellets from chicken dung? What equipment is required for chicken manure granule making? In general, besides chicken manure pellets machine, you may also need to buy dehydrator, compost machine, crusher, mixer, screener, dryer, cooler, coating, packaging machine, etc. Using these fertilizer machines, you must be able to prepare chicken poop fertilizer granules you need!

What equipment can you use to make chicken manure more suitable for granulation?

Usually, it is not advisable to process fresh chicken waste with the fertilizer granulation machine directly. There are two reasons. For one thing, it contains many pathogens, parasite eggs and metal elements, which will cause damage to soil. For another, fresh chicken manure has a high moisture content and big particle size. They will affect the granulation effect and fertilizer pellet appearance. Therefore, before start chicken dung granulation, you need to process it with equipment as follows:

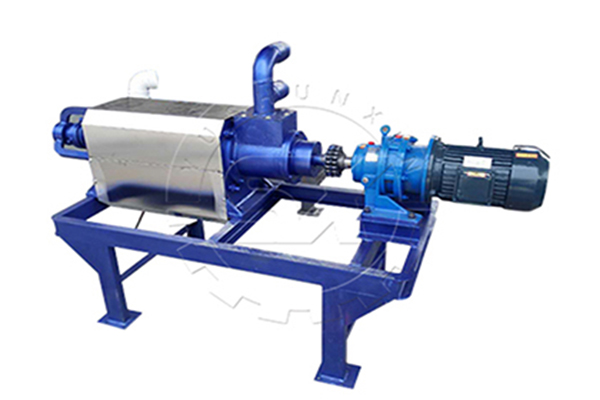

Manure dehydrator

To make chicken manure into pellets, the moisture must not exceed 45%. Because with high moisture content, chicken manure cannot combine with each other and form fertilizer pellets. But manure dewatering machine can reduce the water content of broiler waste to 30%-40% in several minutes. Which is suitable for making chicken manure into granules.

Chicken waste composting machine

As mentioned above, fresh chicken droppings contain many harmful substances. So in order to produce quality broiler waste fertilizer, it is necessary to remove them from manure. Then, what can you do? Composting! How to compost chicken dung? Piling it into strips? Of course not. You also need to turn chicken manure strips regularly to aerate it. At that time, manpower alone is not enough, you need to buy professional chicken litter composting equipment.

Chicken manure crusher

In addition, if you want to produce chicken dung into fertilizer particles with a required diameter and beautiful appearance. You need to feed it into fertilizer crusher after composting, which can make chook poop into fine powder. Because composted broiler manure is still easy to stick to each other to form into agglomerates. In the process of granulation, the agglomerated chicken poop will prepare pellets with a large size and uneven appearance. The finer the chicken dung powder, the better the granulation effect, the higher the competitiveness of your fertilizer.

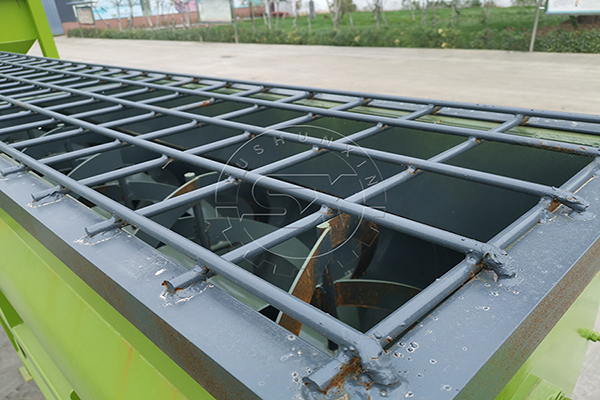

Mixer for broiler droppings

In order to enrich the nutrient content of chicken litter fertilizer granules, we usually choose to add some auxiliary materials. Such as straw, sawdust, soya bean residues, NPK, zinc, etc. But just adding them into chicken dung doesn’t give them the full benefit, you need to blend them with chicken poop evenly. Here, the mixing machine can help you a lot.

Which chicken manure pellets machine is suitable for you?

Next, the most important part-chicken manure granulation. In this process, granulation equipment selection has a serious impact on output and quality of final fertilizer granules. For help you finish chicken litter pellet production smoothly, we design various manure granulators for your choice. Commonly, they can be divided into two parts: wet chicken manure pellets machine and dry chook poop pelletizer.

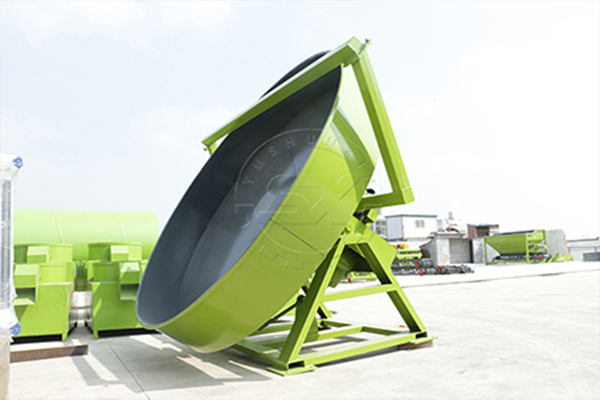

Disc granulator for small chicken manure granulation

When you need a wet chicken manure granulator for small scale chicken waste pellet making, we recommend you choose disc granulation equipment. It is not only because this machine has an output of 1-6 t/h, but also because it has a high granulation rate (over 93%). Moreover, in order to help you finish wet granulation of chicken waste smoothly. We design a spray device above the disc, so you can adjust the moisture content of chicken litter pellet making in an easier way.

Rotary drum pelletizer for large commercial pellet making

But if you plan to setup a large chicken manure fertilizer granulation line, rotary drum pelletizer is your best choice. Besides water adding device, this machine also upgrades its corrosion resistance. It is equipped with rubber lining and clean holes. So it can even withstand the corrosion caused by making 30 tons of chicken manure fertilizer particles per hour. So most fertilizer manufacturers prefer to purchase it for large scale fertilizer granulation of broiler litter.

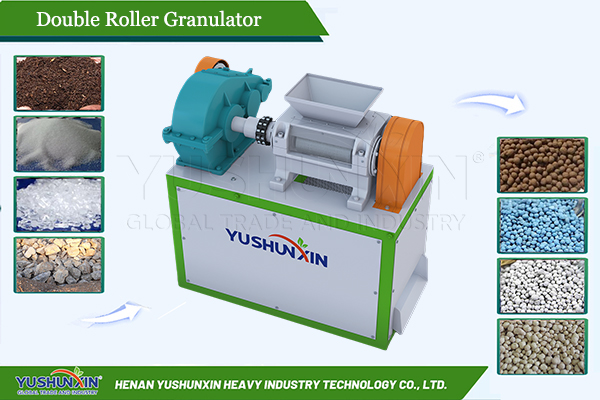

Dry pelleting equipment for low investment chicken waste granulation

Is there a simpler chicken dung pelletizer, which needs a lower investment? Of course. Dry granulation equipment. Only the water content of chicken poop is lower than 15%, you can start chicken manure granulation without drying and cooking. Hence, you can reduce the cost of dryer and cooling buying and drying fuel preparing. In general, there are 2 types of dry fertilizer pelletizers you can buy for chicken dung fertilizer granules making. Double roller granulator, which can produce flat ball chicken manure fertilizer pellets with 3-10 mm for you. And, flat die pellet mill, which is suitable for finish the project at a lower cost.

What can you do to further improve the quality of chicken waste fertilizer pellet?

Is the granulator the end point of chicken manure pellet production? The answer is no. After granulation, you can further improve the quality of chicken dropping pellet by the following steps:

Chicken manure pellets polishing

In general, the pellets produced by flat die granulation machine is cylindrical. Do you want to process it into round chicken manure granules? Polishing machine can help you a lot. In addition, after polishing, your chicken manure fertilizer granules will also have a smooth appearance and higher competitiveness.

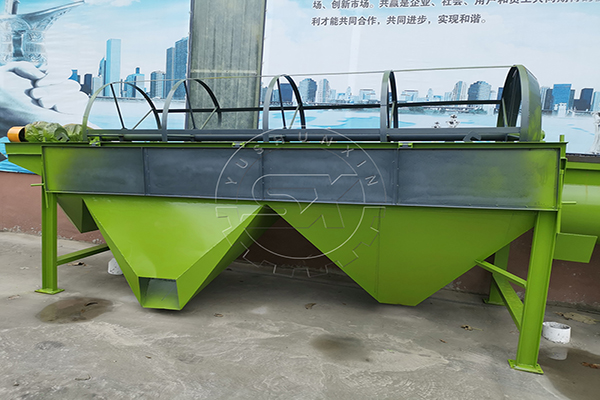

Chicken dung granules screening

This process is designed to remove any oversized or undersized pellets, ensuring that only properly sized pellets are used for fertilizer application. In this way, chicken manure fertilizer pellets you make can provide nutrition to plants evenly and efficiently.

Drying and cooling for wet chicken manure granulation products

For processing chicken manure with wet granulation method, it is essential to focus on moisture content control. Generally, after wet granulating, the water content of chicken manure particle is 15%-20%. However, the international requirement for organic fertilizer pellet production is 14%. So you need to buy dryer and cooler to further dry chicken manure fertilizer.

Coating finished chicken poop fertilizer particles

Do you want to produce chicken dropping pellets with a long fertilizer effect? If your answer is yes, add a coating machine to your chicken manure pellet machines list. Because coating machine can create a protective film to prevent nutrient loss and slow down the release speed.

Packaging to sell

Finally, you also need to buy a fertilizer pellets packaging machine for your chicken waste pellet making business plan. Because after bagging, the fertilizer granules are more convenient to transport, store and use.

In addition, we also can offer you many others fertilizer granulation plans. Such as cow dung pellet machines, npk granules making system, biogas waste to fertilizer pellet technology, etc. Welcome to contact us for your own fertilizer business plan now!