For those who want to produce organic fertilizer with a richer nutrient content, bio fertilizer manufacturing is an ideal choice. On 5th June 2023, a customer from the United States inquired about how to make bio fertilizer. This client planned to use cattle manure, biogas-slurry, ricebrand or husks, tithonia diversifolia leaves, cassava dregs and azotobacter as raw materials. And the output is about 20 tons per hour. But he hesitated whether to produce powder organic fertilizer or granular? According to the biofertilizer making budget, we send him a system involves 5 t/h new type granulation and 15 t/h powder bio fertilizer production design.The following are the specific details of communication in this case:

How to produce 20 tons of bio fertilizer from cattle manure?

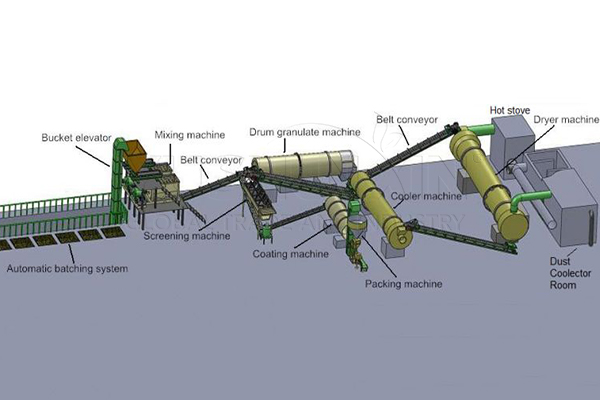

If you want to make biofertilizer in the United States with 20 TPH output, we recommend you buy a rotary drum granulation line. Because it has advantages of large capacity and high erosion resistance.

In general, it consists of 9 parts. Including wheel compost turner, dynamic batching machine, SXFLF-1000 vertical compost crusher, double shaft horizontal mixers, SXZGZ-3210 rotary drum granulator, SXGS-2080 sieving machine, SXHG-2424 compost dryers, SXHG-2424 rotary coolers, fertilizer coating equipment and double bucket packing machine. In general, the large scale organic fertilizer making line costs about $500,000.

Can you give me a more cost-effective bio fertilizer making factory ooperation plan?

The American biofertilizer manufacturer told us his budget for the bio fertilizer production project is $300,000. Is there a more cost-effective solution? The answer is yes. For starting 20 TPH bio organic fertilizer manufacturing from cow dung with $300,000 investment, you can choose buy a combination of a 15 t/h powdery biological fertilizer making line and a 5 TPH organic biofertilizer granulation system. Here, 20 TPH capacity bio fertilizer equipment, it needs these as follows:

Wheel type compost equipment for large scale fertilizer composting

Turning raw materials piles to facilitate composting process to kill harmful substances in cow manure and niogas slurry. For 20 t/h large scale organic composting, we recommend you use wheel compost turner. Because its turning span is 8-30 m, which is wider than other organic fertilizer compost machines.

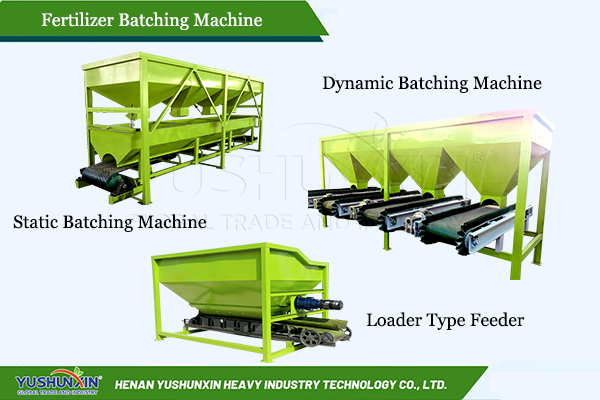

Fertilizer material batching machine for sale

After composting cow dung and biogas slurry, you need to feeding them with rice husks, tithonia diversifolia leaves, cassava dregs, etc. Here, dynamic batching machine can help you control proportion of every raw materials strictly. In addition, the material hopper number can designed according to your requirement

Vertical crusher for large scale biofertilizer manfuacturing

Next, it is time to crushing cow dung compost mixture into fine fine powder. For this, the vertical fertilizer crusher is the best choice. For one thing, its large capacity is suitable for you. For another, there is no screen mesh. So, it can grind biofertilizer compost without blocking.

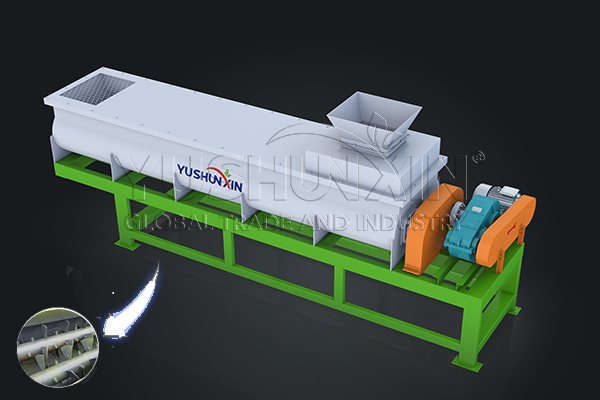

Double shaft mixer for better bio fertilizer making

For the combined bio fertilizer making line, it is advisable to add azotobacter bacteria during mixing. In this way, you can make azotobacter organic fertilizer into powder and granules easier. Here, you need two sets of double shaft horizontal mixers.

Then, for 15 TPH powdery cow dung biofertilizer making, you can transport 3/4 products to double bucket powder fertilizer packing machine. At the same time, the left compost powder will be sent to produce bio organic fertilizer granules.

What equipment is used in 5 t/h bio fertilizer granule production line?

After mixing and azotobacter adding, the material need to pass the following machines to make cow manure biofertilizer pellets.

In sum up, a complete 10 t/h bio fertilizer granulation line consists of windrow composter, batching machine, semi-wet materials crusher, powder screener, mixer, new type/ flat die granulator, pellets sieve, (dryer and cooler), coating machine, automatic packaging scale and belt conveyor.

The above are details about our communication with the customer about bio fertilizer making in the United States. In addition, we can also provide you with many other fertilizer making business plans. Such as organic fertilizer production plan, NPK fertilizer making line, etc.