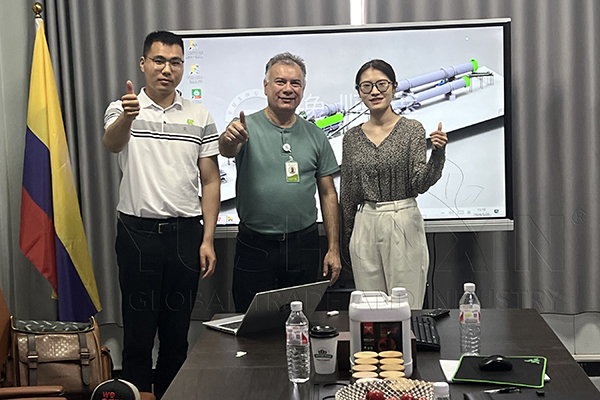

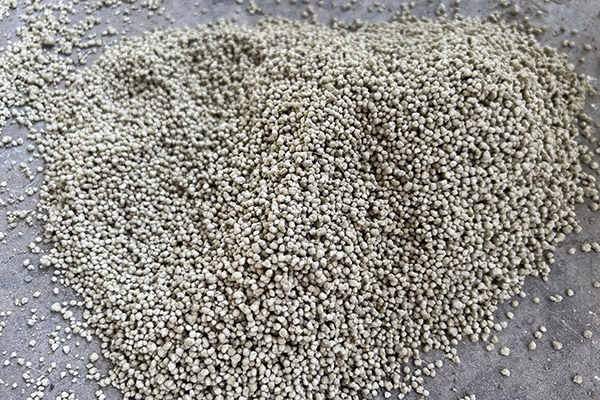

Bentonite is absorbent aluminium phyllosilicate clay. So it is widely used as a binder, absorbent, and carrier in organic fertilizer making and chemical fertilizer production processes. In addition, because of good hygroscopicity, bentonite is also an ideal material for cat litter production and soil conditioner. At that time, it is usually processed into granules. But how to make bentonite granules? On 5th July 2023, a customer from Colombia inquired about it. Finally, according to his requirements, we recommend him pan pelletizer. And the customer gave us good feedback. The following are the specific details of our communication in this case:

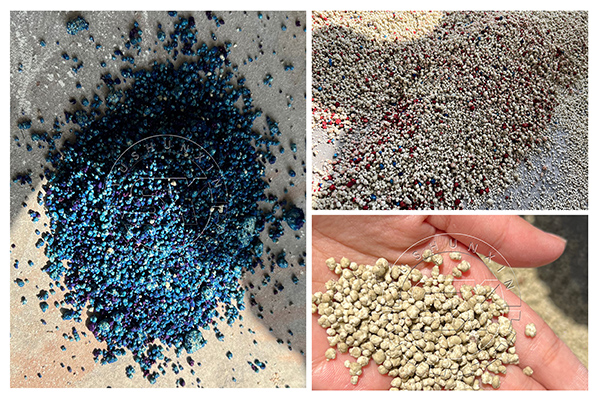

Can I use water as a binding agent to make bentonite granules?

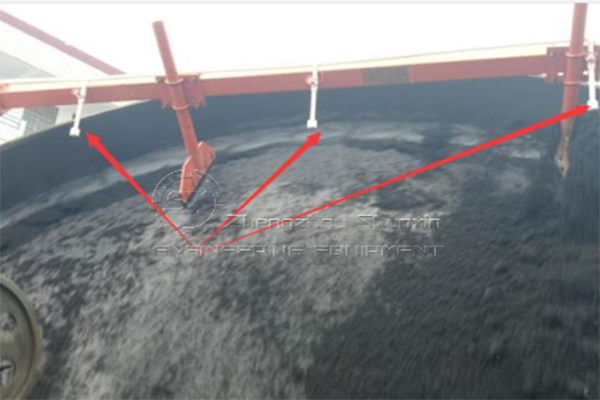

Of course. The customer from Colombia use bentonite powder as material. And for powder, water is an excellent choice for using as binder to enhance the cohesive force between powder. So that you can turn bentonite powder into pellets quickly and effectively. In general, this method is called wet granulation method. Here, YUSHUNXIN has two types of fertilizer granulators for your choice. Pan pelletizer and rotary drum granulator. They both can be equipped with water spray devices to help you control water volume easily. Then under the action of pan or drum rotating, bentonite powder will roll and combine together to form into bentonite pellets.

Which fertilizer granulation machine is suitable for 10,000 tons/year Bentonite pellets making?

In addition, to buy suitable equipment for bentonite granules production, capacity is also an item you must focus on.

| Eqeuipment | Model | Capacity (T/H) | Granulation Rate | Pricing | Feature |

|---|---|---|---|---|---|

| Pan Pellet Machine | SXYZ-3000 | 2-4 | >93% | $4,560 | Small area |

| Rotary Drum Granulator | SXZGZ-1560 | 3-5 | >90% | $7,625 | Rubber lining |

Finally, considering the budget for bentonite granulation plant setup in Colombia, the customer choose to buy the disc granulation machine.

How to produce bentonite granules with 3mm size?

Then for particle size, the customer from Colombia wanted to make bentonite granules with a diameter of 3 mm. But how to adjust the size of final bentonite granules you produce? For disc granulation line, there are two methods for fertilizer pellet size chaging.

Adjust the moisture content

The higher moisture content, the larger size; the lower moisture content, the smaller size. Why? The high water content makes materials easier to stick to each other and combine with more materials. So it is easier to roll into larger fertilizer granules.

Change the angle of disc

The sharp slope, the smaller size; the slower slope, the large size. However, what you need to focus on is that it is advisable to keep the angle of disc between 35° and 55°.

The above are details about our communication with the customer about making bentonite granules in Colombia. In addition, we also have other bentonite pellets manufacturing plans for your choice. Such as large scale bentonite drum granulation system, dry bentonite granulation plan, etc. Or if you need other fertilizer pellets making business plans, we can also provide you with the best solutions. Such as cow dung fertilizer granulation line, NPK fertilizer pellets production system, etc.