When you make animal manure into fertilizer, there is an item you must focus on. It is the moisture content of your manure material. In general, fresh animal manure has a water content of 70%-80%. But it is not suitable for organic fertilizer making, especially when you want to make organic fertilizer pellets. For example, on 23rd May 2023, a customer from India inquired about cow manure drying machine. According to his requirements, we recommend our 2-3 t/h manure drying system. The following are the specific details of our communication in this case:

What are the requirements for cow manure drying from the Indian customer?

Processing 2,500 heads of cow manure in the farm

Reducing moisture content of cattle waste from 70% to 20- 25 %

Can operate to dry cow dung round the year

What capacity of cow manure drying machine can dispose of waste from 2,500 heads farm?

How fertilizer drying equipment works to reduce cow manure water content from 70% to 20-25%?

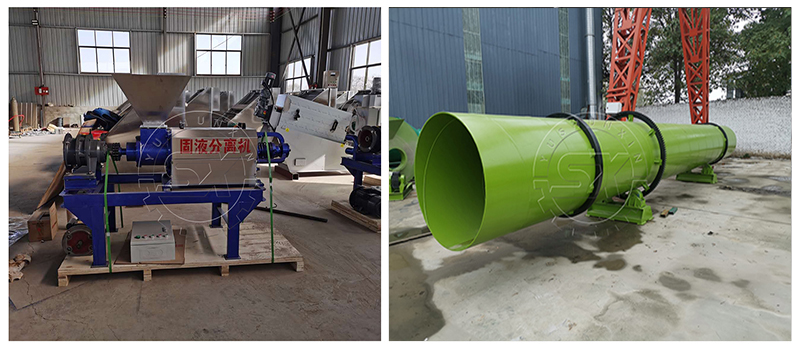

As mentioned above, this Indian client wanted to reduce the cow dung moisture content from 70% to 20-25%. For this, we recommend two fertilizer drying machines.

Can cow manure drying system machines operate round the year?

If you want to start large scale organic waste composting at a low cost, it is an ideal choice to buy crawler type windrow compost system. Because it can greatly reduce the cost of building fermentation trenches. Then how does this large scale compost system work to turn organic materials into compost fertilizer?

In the past, the customer from India processed large quantities of raw cow dung using biological culture and sun-drying methods. But the production must come to halt during the rainy season, thereby increasing the overall production cost of cow manure fertilizer production. Therefore, he wanted to buy drying machine which can operate round the year for moisture reduction in cow dung. SX cow manure drying machine system can fully meet the requirement.

Drying around the year

The above are details about our communication with the customer about drying cow manure in India. In addition, if you want to further make cattle manure into marketable fertilizer, we also can provide you with suitable fertilizer making business plans. Such as powder fertilizer making line, cow manure granulation system, etc.