When you want to use organic waste as fertilizer, it is necessary to make it into compost fertilizer. Because composting is a process of eliminating pathogens, pest eggs and an unpleasant smell in organic litter. Then how to decompose organic fertilizer quickly and easily? Large scale compost system is an ideal choice for you. It has characteristics of large capacity and high automation, these are greatly beneficial for speeding up your organic fertilizer composting. And in order to fully meet the requirements of organic fertilizer suppliers, YUSHUNXIN especially design various large scale compost systems for your choice. You will find the right one for yourself.

What kind of large scale compost system can decompose organic fertilizer quickly?

Compared with small scale organic fertilizer fermentation, it will undoubtedly take more time to start fertilizer composting in a large scale. Thus, how to speed up your large scale compost making process? Here, our engineers have three tips for your reference.

Crushing organic material in fine powder

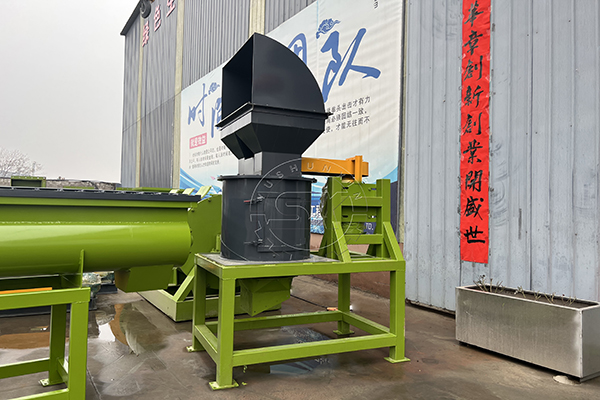

The best way to process organic waste into compost is aerobic fermentation method, which decomposes organic waste in the presence of oxygen. Therefore, providing enough oxygen is the prerequisite for better large scale organic fertilizer fermentation. But how to transport oxygen into compost piles effectively? It is a good idea to crush raw materials into fine powder, which has a larger contact area with oxygen. So, if you want to compost organic litter quickly, it is an excellent choice to buy a crushing machine for your large scale compost system. For this, you can choose new type vertical grinder or semi-wet material crusher.

Mixing materials with biological bacteria/old compost

In addition, you also can facilitate large scale composting by mixing raw material with old compost. Because it contains more microorganisms which are responsible for decomposing organic matter and generating heat to kill harmful substances in organic waste. Of course, it is more convenient to add biological bacteria directly. But no matter which method you use, it is necessary to mix addition with organic litter evenly for making it give full play active role in large scale composting. Here, we recommend you use horizontal mixer or disc blender in your large scale compost system.

Focus on temperature control

Then if you want to speed up organic fertilizer fermentation, you also need to pay attention to temperature adjustment. During large scale composting, it is advisable to keep the temperature at 60℃-70℃. Because when the temperature reaches 60 ℃, the pathogens, pest eggs and grass seeds in manure can be killed. However, if the temperature is higher than 70℃, it will cause the death of beneficial bacteria. At that time, you need to use compost equipment to turn materials to dissipate excessive heat.

Therefore, a quality large scale compost system usually consists of crusher, mixer and compost equipment. And according to the different customers adopt, we design various types of large scale composting systems for organic fertilizer making. You can choose the right one according to your needs.

Which is the largest compost system of organic fertilizer?

Among all large scale organic fertilizer composting systems, the wheel type compost system is the largest fertilizer fermentation line in our factory. It is also the best hot selling product for fertilizer organic manufactures who want to start large scale composting in fermentation groove. There are three reasons as follows:

How to start large scale organic waste composting at a low cost?

If you want to start large scale organic waste composting at a low cost, it is an ideal choice to buy crawler type windrow compost system. Because it can greatly reduce the cost of building fermentation trenches. Then how does this large scale compost system work to turn organic materials into compost fertilizer?

Crushing and mixing

As mentioned above, crushing and mixing are both essential for large scale composting of organic waste. The former is helpful for transporting oxygen into manure compost piles smoothly and quickly. The latter is beneficial for giving full play to the role of starter to shorten fermentation time. You need to finish them before the windrow composting.

Piling materials into long windrows

Then you need to pile processed organic manure into long windrows on the flat ground. Because it is convenient for starting large scale fermentation with crawler type windrow compost turner. Moreover, it is advisable to pile organic litter into windrow with a width of 2.4-3 m and a height of 0.6-1.5 m.

Driving crawler type composter

Finally, it is time to operate crawler type composter to compost windrows in a large scale. Is this windrow composting machine difficult to operate? Of course not. Because it adopts a double control rods operation system. Even semi-skilled worker can drive it to compost a large amount of organic litter easily. Usually, it can help you process 500-1500 ㎡ of windrow compost per hour.

How to prepare large scale compost more environmentally friendly?

Is there a large scale compost system suitable for starting aerobic fermentation in an environmentally friendly way? In this case, our vertical fermentation tank system is your best choice. It mainly relies on two designs to reduce fertilizer making pollution.

In-vessel composting

That is, vertical fermentation pot generally composts organic manure in a closed environment. In this way, it can prevent diffusion of odors and harmful substances during large scale compost making. In addition, in-vessel composting method is also beneficial for isolating outside the world influences. So you can make fertilizer compost in a large scale better and faster.

Exhaust gas treatment system

Moreover, we design an exhaust gas treatment device for this large scale compost system. It will treat composting waste gas until it reaches the emission standard. And then discharge it. It can further ensure that you can start large scale composting with less pollution.

After large scale compost making, we also can provide you with compost granulation systems according to your material, budget, area, capacity, etc. Welcome to contact us to ger your own fertilizer business plan immediately!