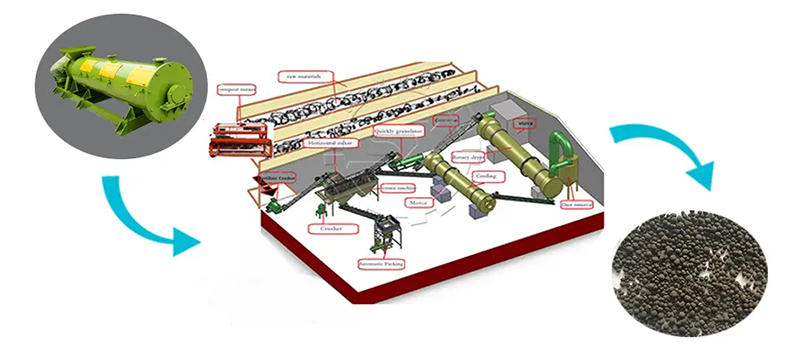

For those who want to make more profits from organic fertilizer production, the best choice is prepare organic fertilizer into granules. And for small-medium scale organic fertilizer manufacturing, 30,000 t/y new type organic fertilizer granulation line is an excellent choice. It can dispose of the large amount of manure waste in your farms. In addition, the produced organic fertilizer pellets have a higher hardness, which makes fertilizer more convenient to transport, store and use.

Who needs the 30,000 t/y new type organic fertilizer granulation line?

When you want to know is this 30,000 t/y new type organic fertilizer making system suitable for you, it is advisable to consider from three aspects: capacity, final fertilizer products, cost.

Capacity

If you make organic fertilizer making line work for 300 days a year, it can help you produce 100 tons of pellets a day. Then generally, the ratio of liquid and solid manure (used in organic fertilizer production) is 2:1. So, through it, you can process 300 tons of manure a day. This means if you operate a farm which has 10,000 cows or 1,000,000-2,000,000 birds chicken or 30,000-40,000 pigs, this 30,000 t/y organic fertilizer preparation plan is an ideal choice for you.

Final fertilizer products

Looking at the final fertilizer granule is an effective way to know is the new type organic fertilizer production line right for you. In general, this production system can meet your requirements of making 2-5 mm organic fertilizer granules and its granulation rate can reach 97%. In addition, the hardness of its granules will be better than pan granulator or rotary drum granulator. That is, the final fertilizer has a lower possibility of pulverization and is easier to transport, store and use.

Cost

During purchasing, organic fertilizer making line cost is an item you must focus on. For a complete 30,000 t/y new type organic fertilizer making system, you need to prepare $160,000-$250,000 (reference price). But the price will change with the equipment configuration, number, and even time. If you need a precision quotation, please contact us immediately.

Why use new type organic fertilizer granulator in 30,000 t/y organic fertilizer making system?

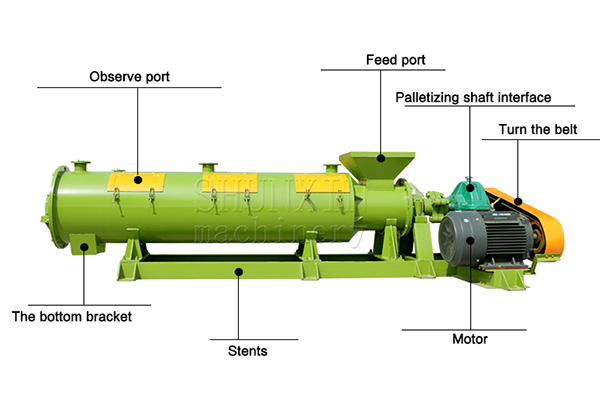

New type organic fertilizer pelletilizer is an excellent choice for 30,000 t/y organic fertilizer manufacturing plant setup. There are three reasons.

Quality organic fertilizer pellets making

The new type organic fertilizer granulator mainly makes use of high speed rotary mechanical agitation force of stirring teeth and the resulting aerodynamic to granulate organic material (this is the reason why it is known as stirring teeth granulator). So its final pellet product has higher hardness. This is beneficial for transport, storage and use.

Suitable capacity

As mentioned above, when you want to process 30,000 tons of organic fertilizer granules, you need an organic fertilizer pelletizer with a capacity of 100 t/d. That is, about 5-6 t/h. Therefore, SXJZ-1200 new type organic fertilizer granultor, which can prepare 4-6 tons of pellets, is the best choice.

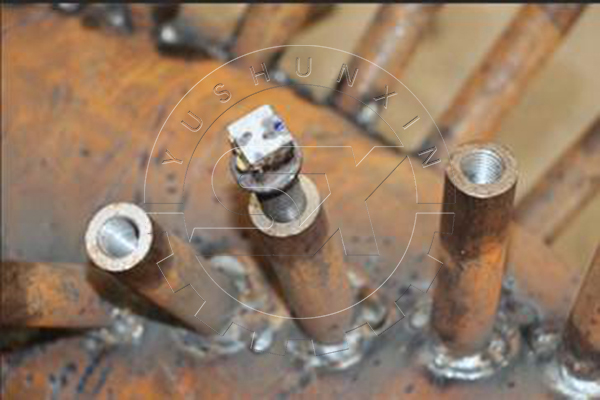

Long service life

In addition, this granulation equipment has a long service life. On the one hand, the material for stirring teeth is manganese steel, which has high strength and high erosion-resistance. On the other hand, its wearing parts – stirring teeth only need to be replaced every six months or one year. And it is easy to finish.

What equipment is commonly used after new type organic fertilizer granulation?

This equipment can sieve out required size organic fertilizer granules to transport them to the next process. At the same time, the leftover small or large particles will be returned to reprocess. In other words, you can produce granular organic fertilizer with nearly no waste.

Finally, in order that finished organic fertilizer can be sold in a targeted way, you can package it in 10 kg/bag, 25 kg/bag, 50 kg/bag, etc. For this, we can provide you with single / double bucket automatic fertilizer bagging machine.

Besides the above fertilizer making equipment, we also can provide many other machines for 30,000 t/y new type organic fertilizer granulation line. For example, polishing machine for making pellets more rounded, coating machine for long fertilizer effect, dust collector for less pollution, etc. If you have any other requirements, welcome to contact us immediately.

Partial parameters of 30,000 t/y new type organic fertilizer granulation line

| Equipment | Model | Capacity (T/H) | Power (KW) | Dimension (MM) |

|---|---|---|---|---|

| Dewatering machine | 5-6 | |||

| Crawler windrow composter | SXLDF-2800 | 1100-1300(m³/h) | 123 | |

| New type vertical crusher | SXLFL-800 | 5-8 | 30 | 1800*1020*2700 |

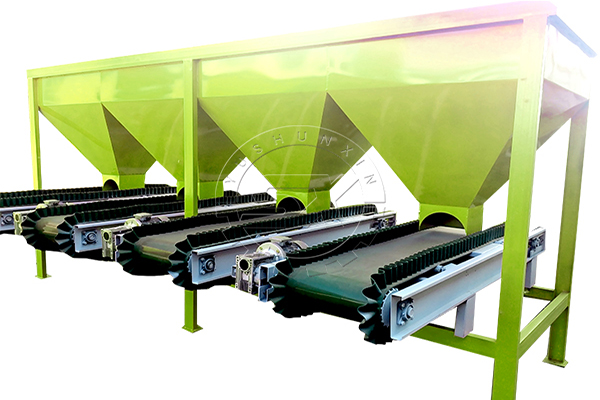

| Double shafts horizontal blender | 5-8 | |||

| New type organic fertilizer pelletizer | SXJZ-1200 | 4-6 | 90 | 4900*2550*1800 |

| Rotary screening machine | SXGS-1540 | 5-8 | 5.5 | |

| Rotary drying machine | SXHG-1616 | 6-8 | ||

| Rotary cooling equipment | SXLQ-1616 | 6-8 | ||

| Automatic packaging scle | ||||

| Dust collector | ||||

| Belt conveyor |

Is the other designs for 300,000 TPY organic fertilizer granulation plant setup?

Of course. And our customers had make profits by them. For example, there are 5 t/h rotary drum organic fertilizer granulation line to USA, 100 t/day Organic fertilizer making cost in Brazil, 6 t/h cow dung fertilizer making, etc

Moreover, there are also organic fertilizer manufacturing plan with other capacities, such as 20,000 ton/year organic fertilizer granulation plan, 50,000 TPY organic fertilizer production, 100,000 organic fertilizer making machines, etc. Welcome to contact us for your customized fertilizer business plan now!