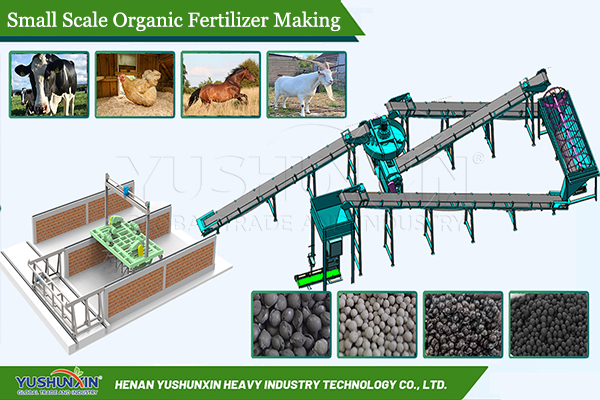

Do you require a way for disposing of farm manure? Are you trying to find a way to develop your organic fertilizer business? But you have no previous experience of making organic fertilizer from animal manure. Here, you can start with small scale fertilizer manufacturing. Usually, it can help you produce 1-10 tons of organic fertilizer per hour. And it has characteristics of low investment, easy operation, less space occupation, etc. So it is an ideal choice for beginners who want to setup an organic fertilizer plant. Then how to start small scale organic fertilizer production? You can consider it from the following aspects:

What do you need to do for starting small organic fertilizer production?

Before starting small scale organic fertilizer manufacturing, you need to know what you should do for it. Generally, you need to pay attention to 3 items: materials, plant location and equipment selection.

Material collection

In general, you can make small scale organic fertilizer with 3 kinds of materials. Animal manure: cow dung, chicken manure, piggery waste, goat poop, etc; Industrial waste: biogas residue, sludge, sugar waste, mushroom waste, etc; Agricultural litter: straw, sawdust, maize stocks, soya bean residues, etc. It is advisable to use the first two as the main material for organic fertilizer making and the last as auxiliary materials.

Equipment selection

Then suitable equipment purchasing is essential for smoothly small scale organic fertilizer production. For this, you need to know what machine is needed in small scale organic fertilizer making? How much does the small scale organic fertilizer making system cost? Can your small organic fertilizer factory accommodate it? But don’t worry, we will help you. Even we can offer you customized design according to your requirements.

How to produce organic compost fertilizer in a small scale?

For small scale organic fertilizer production, composting system is the best economical and simplest choice. When you plan to start a small scale composting with 1-10 t/h capacity YUSHUNXIN can provide fertilizer machines as follows:

Screw dewatering machine for 10-20 m³ manure waste disposal

To make quality organic compost fertilizer you need to dry manure material to 40%-60% first. For this screw dehydrator is your best choice. It adopts a stainless steel sieve with 0.3-0.5 mm holes, which can help you separate solids from excrement of livestock quickly. After manure dewatering, the water content of material can be reduced to 30%-40%.

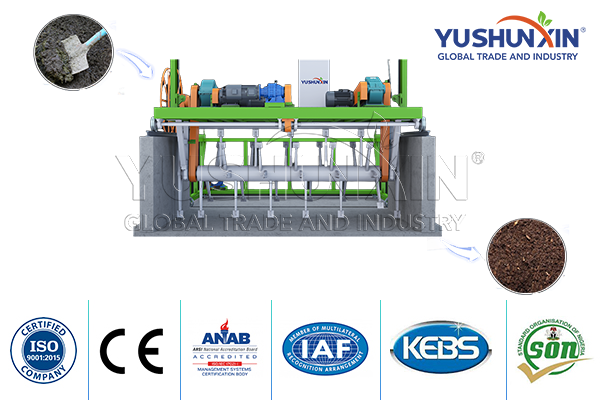

Small composting equipment

Then, you can start organic composting in a small quantites, which plays an important role in removing harmful substances from manure. There are 3 types of fertilizer composting machines for your choice.

| Equipment | Capacity (m³/h) | Compost Time (days) | Infrastructure | Compost Temperature (℃) |

|---|---|---|---|---|

| Groove Type compost turner | 700-2000 | 15-20 | Fermentation Trench | 60-70 |

| Windrow Compost Machine | 500-1500 | 15-20 | Flat Cement Ground | 60-70 |

| In-veseel compostor | 5-150 | 10-15 | Flat Cement Ground | 60-70 |

What equipment is needed in small scale powder organic fertilizer making?

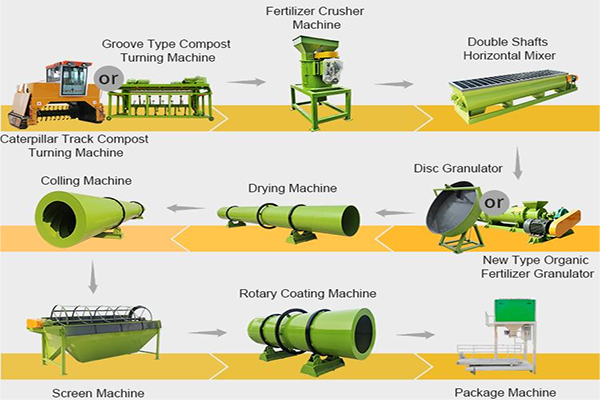

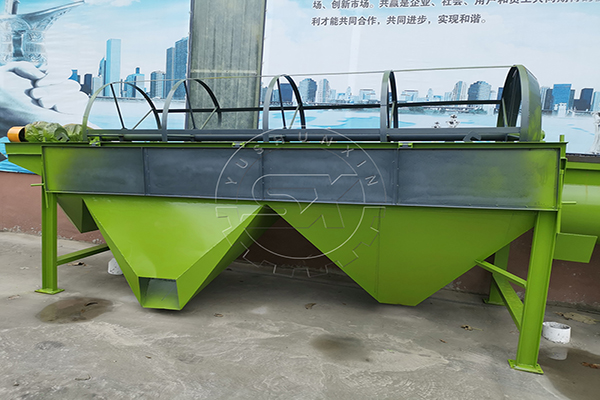

In general, powdery organic fertizer production line contains 5 parts. Dewatering machine, compostors, crusder, mixer, screener and packing machine. So, besides screw dehydrator, groove compost turner, you also need the following small scale organic fertilizer machines.

Semi-wet material crusher for small scale compost powder making

As the name suggests, it is necessary to break agglomerated compost material into fine powder. For small scale organic fertilizer pulverizing, semi-wet material crusher is the best option. It can fully meet your requirements of crushing wet compost material with 1-8 m³ per hour. At the small time, there is no blocking. In addition, it can produce powder organic fertilizer with even 50 mesh size.

Economical disc mixer for powder material

If you use various material in small scale powdery organic fertilizer making, you also need to buy a fertilizer blender to blend different materials evenly. This is key to ensure the nutrient balance of your final fertilizer. Here, it is advisable to purchase disc mixer. It not only has advantages of suitable output – 2-12 TPH, but also low cost, less space occupation, etc.

What is the design of small scale organic fertilizer granulation plan?

What you need to do for small scale organic fertilizer pellet production? It is on the basis of the above composting and powder organic fertilizer making line. If you want to further prepare organic fertilizer pellet in a small quantities, you can process mixed organic compost with 5 steps:

Small organic fertilizer granulator

When it comes to small scale organic fertilizer granulation machine, we can provide you with disc granulation equipment, new type pelletizer, double roller granulator.

| Equipment | Capacity (m³/h) | Moisture | Granule Size (mm) | Feeding Material Size (mesh) |

|---|---|---|---|---|

| Disc Granulator | 1-6 | 20%-40% | 1-8 | 50 |

| New Type Granulator | 1-8 | 20%-40% | 2-5 | 50 |

| Roller Press Granulator | 1-3 | 5%-10% | 3-10 | 50 |

How much does a small scale organic fertilizer manufacturing line cost?

The cost of small scale organic fertilizer production usually varies according to capacity, equipment configuration and many other factors. Here, we will show you the prices of 1-2 t/h small organic fertilizer production line, 3-5t/h small organic fertilizer making line and 5-10t/h organic fertilizer manufacturing system for your reference.

1-2 t/h

- From compost to packaging

- (Reference)

3-5 t/h

- From compost to packaging

- (Reference)

5-10 t/h

- From compost to packaging

- (Reference)

Is there a lower investment organic fertilizer making plan?

Of course. The above is the price of the complete configuration small scale organic fertilizer making machines. In addition, we can offer you simple and economical design. For example, for basic compost turner + granulator, you only need to prepare $ 10,000-$80,000. As for medium design, with composter, crusher, screener, granulator, packaging machine, etc. About $ 50,000-$150,000.

Is there established small scale organic fertilizer plant?

Of course. In the past 20 years, YUSHUNXIN had helped many businesses setup their organic fertiizer plants with small output. They are from contries all the world. Such as 50 TPD biogas waste granulation line in Kenya, small scale biochar compost granulation in Indonesia, 5 t/h pig manure to powder organic fertilizer system in Peru, etc.

Small scale organic fertilizer production line is an ideal choice for beginners and small farm management. But if you have a large animal farm or want to further enlarge your organic fertilizer making plant scale, you can choose our large scale organic fertilizer production plan.