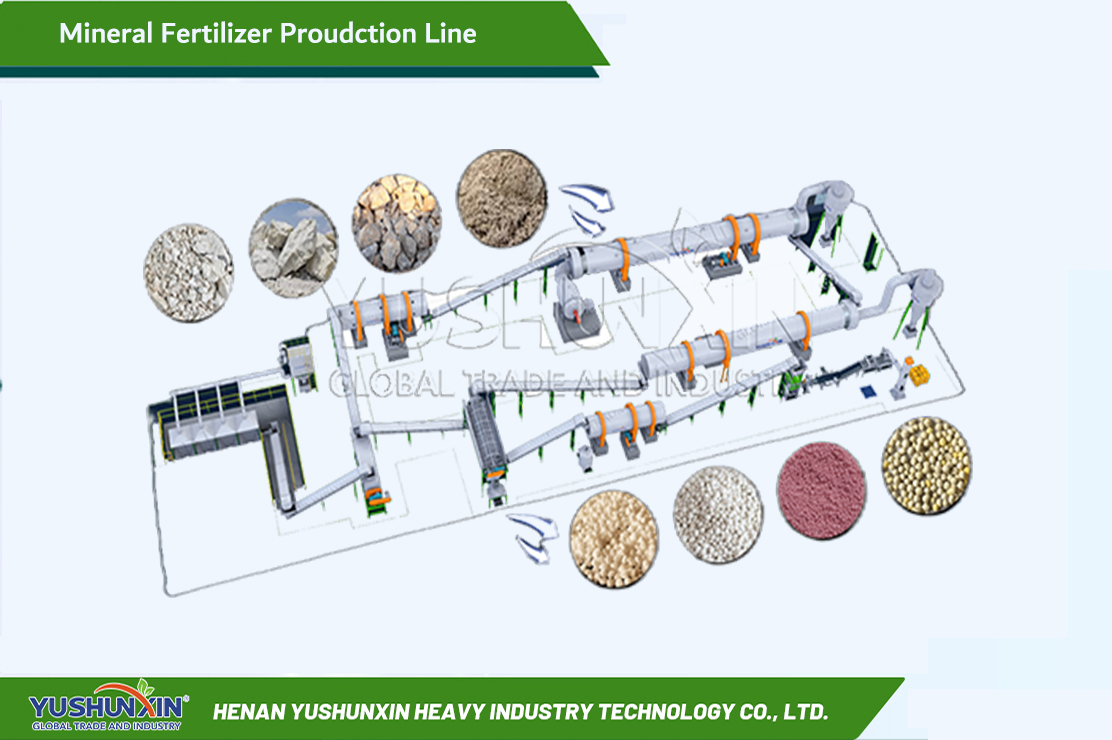

For mine waste management, making into mineral fertilizer is an ideal choice. For this, there are two types of plans for your choice. Making ore waste into fertilizer powder or mine fertilizer granules. Here, as a professional fertilizer equipment manufacturer, YUSHUUNXIN can offer quality machines for mineral fertilizer production. Including ore crusher, mixer, granulator, screen, packing machine, etc. Welcome the contact us to get your own plan for making fertilizer from mine immediately.

2 ways of mine waste management by mineral fertilizer production

Generally, there are two fertilizer making systems for mine waste management as follows:

Ore powder fertilizer making line – simple and economical

If you has a limitation of mine waste disposal or want to start from simple process, we recommend to choose make mine into powder fertilizer. Only need 4 steps, it can help you prepare quality mineral fertilizer. They contains ore crushing, powder mixing, screen and packaging. In addition, because of simpler process of mine waste to fertilizer manufacturing, the system only needs several machines. Therefore, it has characteristics of less area occupation and lower investment.

Mine fertilizer granule production – better ore pellet making

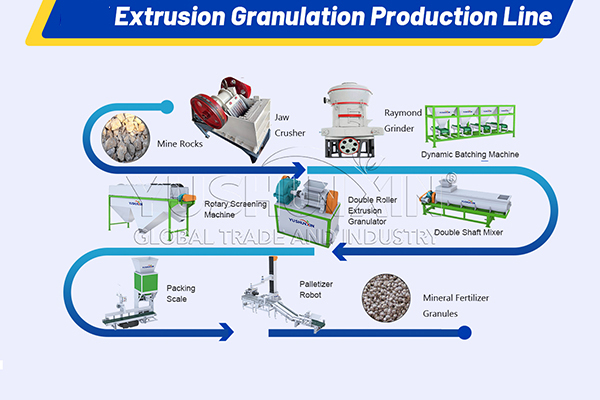

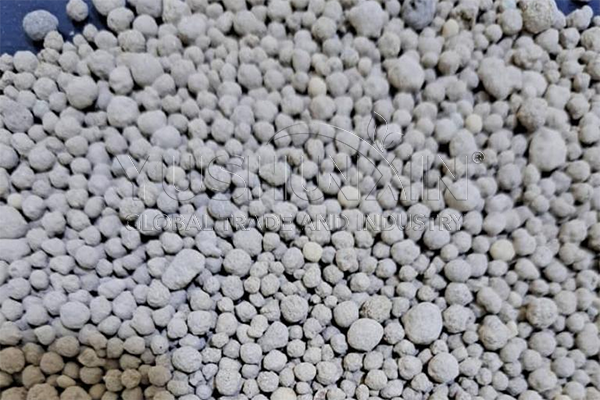

But when you plan to make mine into fertilizer pellet to make more profits, ore powder granulation line is you best choice. After granulation, the mine fertilizer you produce has features of lower sticking possibility, slow release and no nutrient layering. Therefore, it is easy to transport, store and use. The system is popular with commercial mine fertilizer plants. In this process, after crushing, mixing and powder screen, it usually need chemical fertilizer granulator, granule screener and packing equipment.

What crushers are commonly used in ore processing?

From the above, it is obvious that crushing is necessary for using mine as fertilizer. Then, what equipment is suitable for ore crushing? There are two machines.

Raymond grinder

However, for quality mine fertilizer production, you need ore powder with a smaller size. So, you need to process ore rocks with Raymond grinder after Jaw crusher. The mine waste management machine can further crush small mine stones into 100-500 meshes size.

How to buy suitable equipment for making ore rocks into fertilizer granules?

Then, for mine fertilizer granule making, which equipment is the best for ever step? There are tips for purchasing your own fertilizer machine for mine waste disposal.

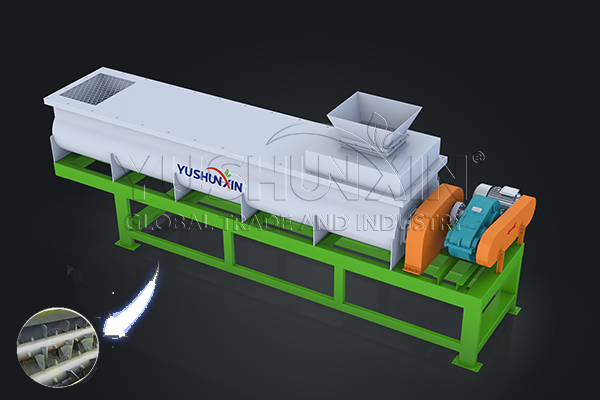

Mixer

In order to make fertilizer with balanced nutrients, we usually add auxiliary material during mine fertilizer production. But, to achieve the goal, it is not enough to just pile them together. You need to mix various material evenly. Here, we design double roller mixer and vertical mixer for your choice. The former has high mixing efficacy and continuous system. The latter is suitable these who has a over 8 t/h powder mixing requirement and purse more economical price.

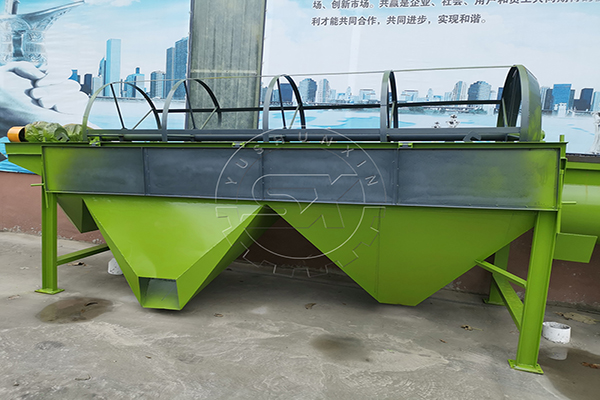

Sieving and Packaging

Finally, there are two steps you need to do. On the one hand, sieving out nonstandard mineral fertilizer granules. In this way, you can greatly improve your fertilizer pellets quality and reduce the material waste. In this step, rotary screen machine is commonly used. On the other hand, it is packaging finished mine granules into bags. There is professional fertilizer packing scale. Automatic bagging and sealing. And the quantitative precise is lower than 2‰.

What types of mineral fertilizers making lines in YUSHUNXIN for you?

In YUSHUNXIN, there are 3 kinds of system for mine waste management is popular with mineral international fertilizer manufacturers.

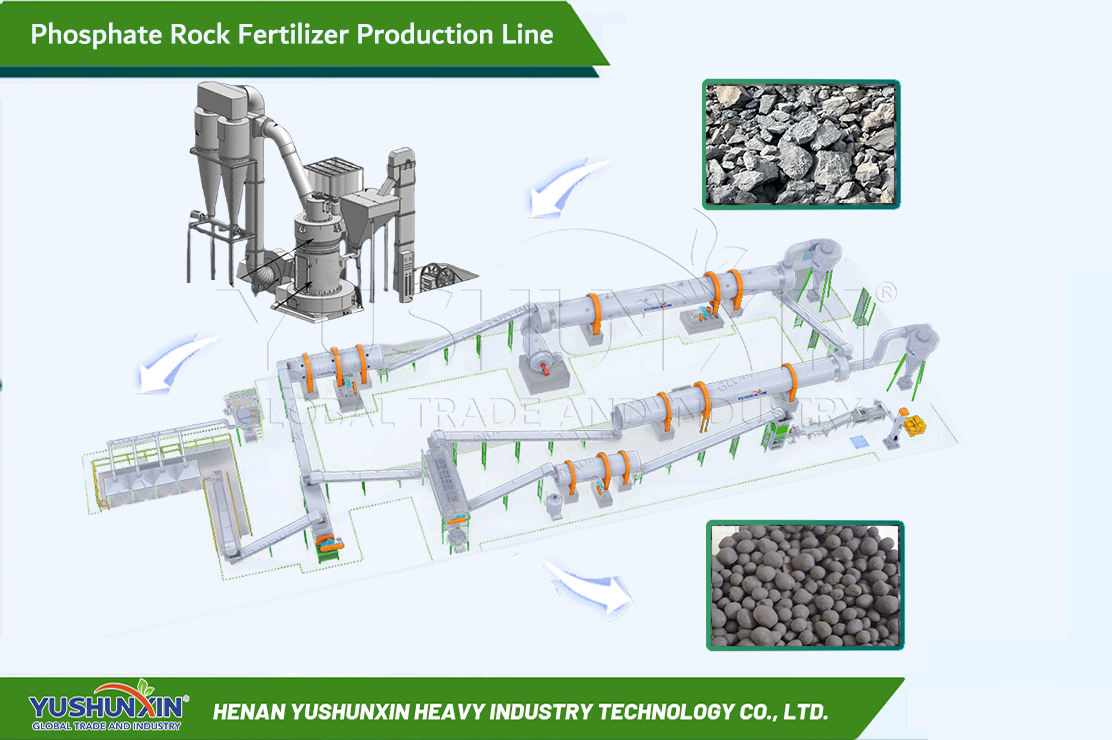

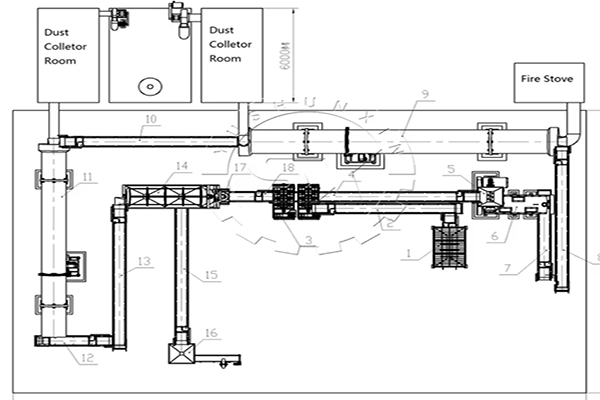

Rock phosphate fertilizer making line is a process of using phosphate rocks and liquid sulfuric acid to make SSP granules. In general, the procedure is Jaw crusher → Raymond grinder → mixer → granulator→ dryer and cooler → sceener → packaging machine. To prevent material erosion to equipment, we can add stainless lining to your rock phosphate fertilizer machines according to your needs.

For limestone granule making, the most suitable plan is dry granulation. The process contains 6 steps. Stone crushing → batching → mixer → roller granulator → screener → bagging machine.

What other mineral materials can be used in making fertilizer

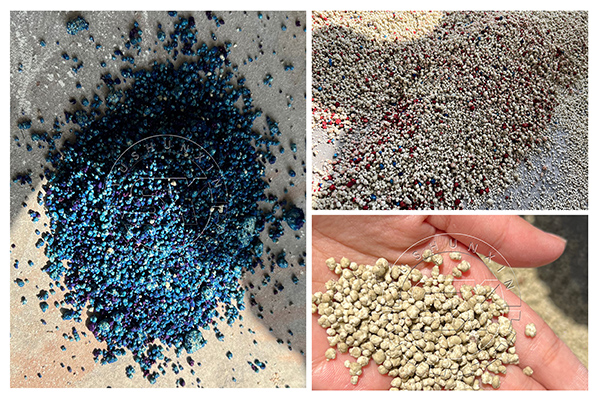

Besides the above ore waste, our mineral fertilizer making also suitable for many other mineral materials. Such as bentonite, clay, zeolite, coal, biochar, etc. Welcome to contact us immediately for your own fertilizer business plan for mine waste management.