On 10th December 2023, there is poultry manure drying machine system delivery to Bengal. It will be transported to the customer who plans to dispose of poultry manure waste in his chicken farms. This Bengali client wanted to collect poultry poop waste from H type Cage conveyor belt that he already has and sells it for commercial purposes. In order to make more profits, the client planned to make it into dry poultry manure with moisture of 20%. Finally, he bought our 20 MT/day manure drying system. Now the drying system has been running to process poultry manure smoothly. The following are the specific details of our communication in this case:

How to dry poultry manure from 65% to 20% moisture?

The email from the Bengali customer showed us that the moisture content of poultry waste is 65%. How to reduce the manure water content to 20%?

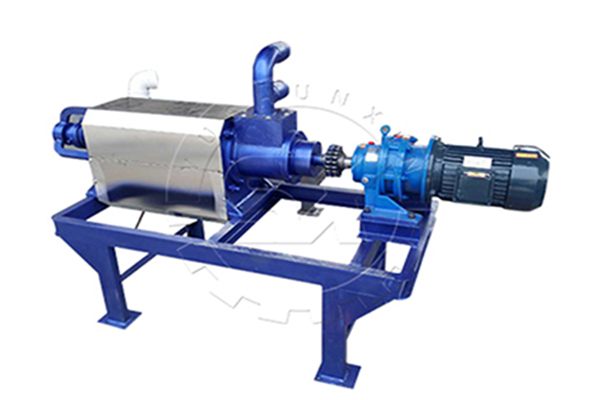

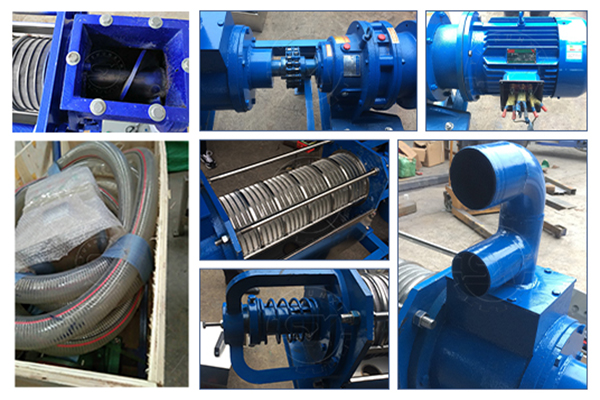

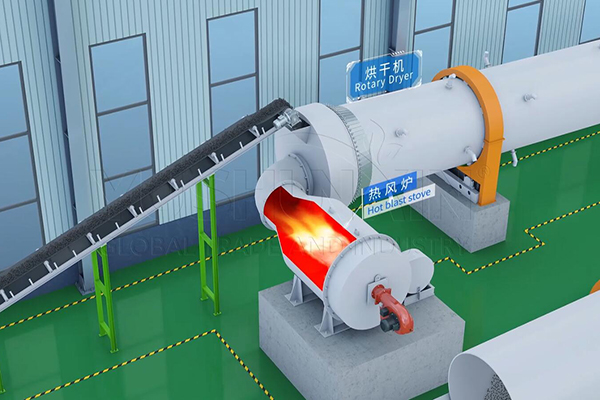

Here, we recommend the fertilizer drying system, which consists of dewatering machine and rotary drum drying machine for poultry manure drying. The former is used to remove excessive water from poultry manure initially by pressing. This can dry poultry poop to 30%-40% water content. Then the latter will make use of hot steam to further dry poultry manure and make the moisture decrease to 20%, even below 10%.

Why not dry poultry manure with rotary drum drying machine directly?

In general, there are two reasons: energy consumption and material waste prevention.

Is there a small poultry manure dryer with 20 MT/day?

How long does chicken manure take to dry?

10-20 minutes

Poultry Manure Drying Time

What is the price of this poultry manure drying system equipment?

The above are details about our communication with the customer about Poultry manure drying in Bengal. In addition, if you want to further to make poultry manure into compost, organic fertilizer pellet, we also can offer you suitable fertilizer business plans and machines.