In Sri Lanka, compound fertilizer plays an important role in agricultural development. So many businesses invest in chemical fertilizer manufacturing, especially NPK fertilizer production. But how to prepare NPK fertilizer in a simple way? It is making NPK bulk blending fertilizer. For this, you need professional fertilizer machines and design. YUSHUNXIN can help you a lot and there are many successful cases. For example, on 9th April 2023, a customer from Sri Lanka inquired about NPK fertilizer blending plant setup. The following are the specific details of our communication in this case:

Is there a business plan for 50 – 100Mt per day NPK fertilizer blending plant setup?

The use of microbial strains is the core of bio organic fertilizer preparation. In general, microorganisms are divided into two types: composting microbial inoculant and functional bacteria. And you need to add them in different stages:

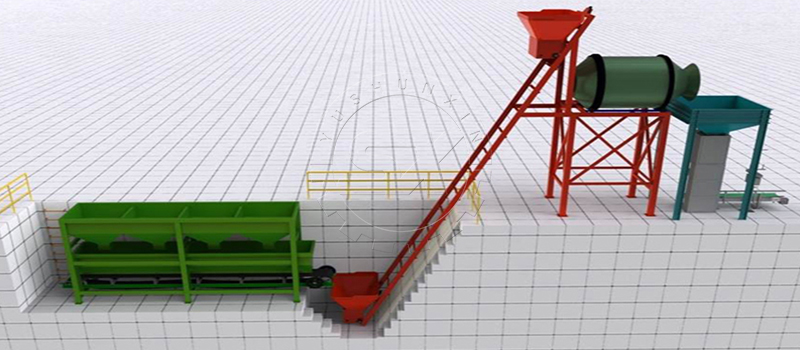

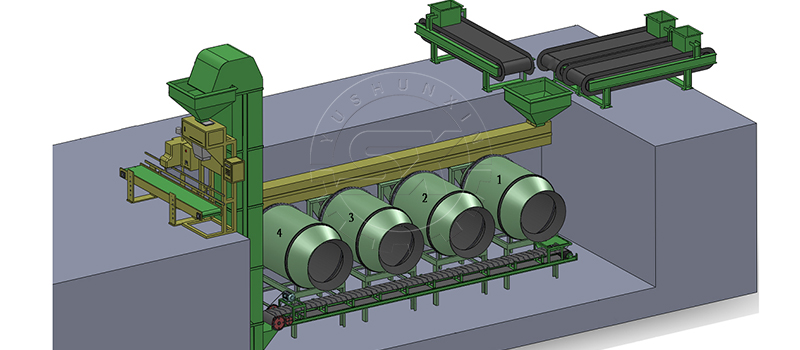

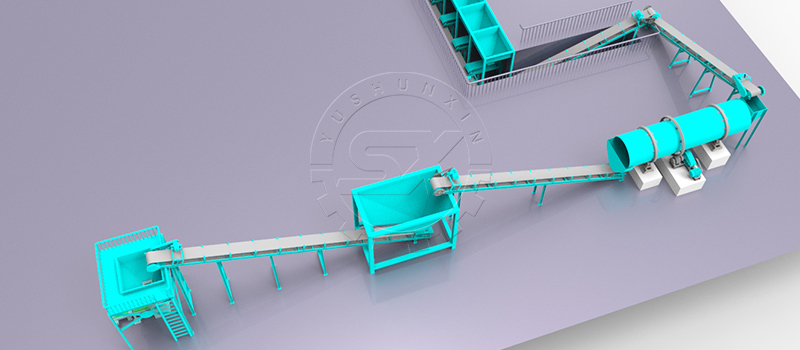

Of course. The client from Sri Lanka wanted to setup a NPK fertilizer blending plant with a capacity of 50 – 100 Mt per day. So we recommend him a 2-5 t/h bulk blending fertilizer making line. You can keep it running two shifts a day and 10 hours a shift. In general, a complete NPK fertilizer mixing line consists of batching machine, BB fertilizer mixer, packaging machine and conveyor. It is simple, but can help you produce quality NPK fertilizer in a short time.

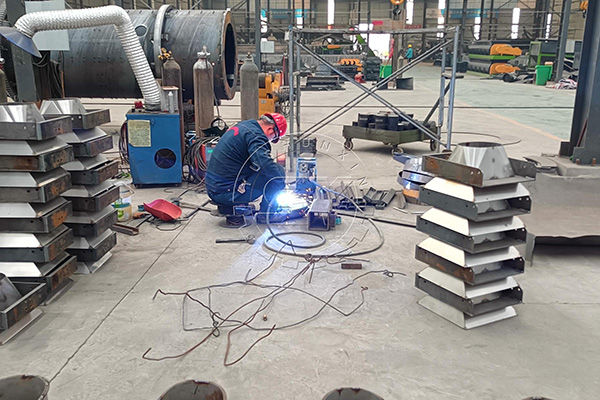

What kind of material is used to make NPK fertilizer machines?

How much does this NPK fertilizer making system cost?

What are all the documents you will provide?

When you pay, we will provide operating instructions, installation drawings, foundation drawings, customs clearance information etc.

The above are details about our communication with the customer about NPK fertilizer blending plant setup in Sri Lanka. In addition, we also can provide you with many other fertilizer making business plans, such as NPK fertilizer granulation line, Double roller NPK fertilizer pellet system, etc.