Do you want to make more profits from cow manure recycling? Are you looking for a project for making cattle manure into high quality fertilizer? Take action and turn cow dung into fertilizer granules! In this process, it is necessary to choose a suitable cow dung pellet making machine. In order to fully meet your requirements, YUSHUNXIN not only design various cow dung pellet making machines for your choice, but also setup different cow waste granulation lines to help you finish cattle litter fertilizer pellet smoothly. Are they affordable for you? Of course, as a leading fertilizer equipment company, we will offer you cow manure granulation machines and business plans at a favourable price!

Top 3 cow dung pellet making machines for your choice

As a professional fertilizer equipment supplier, we can provide you with various organic fertilizer granulation machines for cow manure processing. Among them, there are 3 types of cattle waste pelletizers that are popular with granular cow manure fertilizer manufacturers. They have different features and are suitable for different occasions, you can choose the right one according to your needs.

Pan granulation machine for small cow farm manure disposal

Are you finding a fertilizer granulation machine for your small cattle farm waste disposal? Our disk granulation machine is an ideal choice for you. Why? Because it has features as follows:

Small capacity

Our disc pelletizer can fully meet your requirements for the production of small scale organic fertilizer making from cow farm manure. If your cow farm generates less than 60 tons of manure per day, we recommend you choose SXYZ-2800, which has a capacity of 2-3 t/h. Moreover, we also can provide you with SXYZ-3600, which can help you produce 4-6 tons of cow litter fertilizer particles.

Quality cow manure pellet making

This machine can keep nutrients of cattle droppings in your organic fertilizer particles. So that you can prepare cow manure fertilizer, which can supply rich nutrients to the growth of crops. In addition, it can meet your requirements of making cattle poop fertilizer granules of different sizes. We can offer you mold for 1-8 mm pellets making.

Economical price

With effective cow manure fertilizer granule making, the machine also has an economical price. A 0.5-0.8 t/h output disc pelletizer only needs $3,500. In addition, to buy a 6 t/h pan granulation machine for cow manure fertilizer pellet making, you can only prepare $12,000. So, it is an ideal choice for setup a cattle manure fertilizer granulation line within $100,000 budget.

| Equipment | Pan Granulator |

|---|---|

| Capacity | 1-6 T/H |

| Granule Size | 1-8 mm |

| Granulation Rate | 93% |

| Price | $3,500-$12,000 |

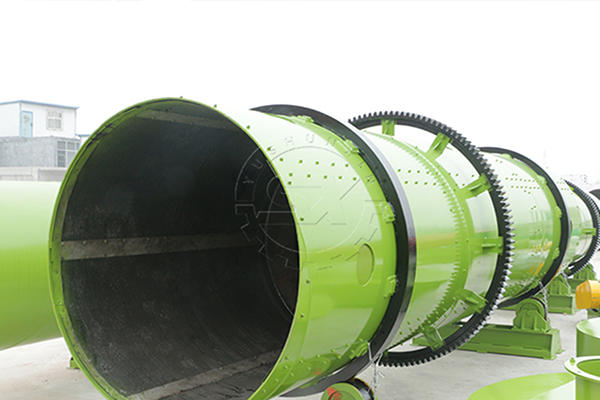

Rotary drum granulation machine for large scale cow dung fertilizer granulation plant setup

Some businesses want to invest in a large scale cow manure fertilizer granulation plant setup. For this, our rotary drum granulation machine is the most suitable one. There are two reasons:

Large capacity

The maximum capacity of it is 30 t/h, That is, only using one granulation equipment, you can produce 2-3 times more fertilizer granules than other cow dung pellet making machines. Meanwhile, its minimum model has an fertilizer granules output of 1-3 t/h.

High corrosion resistance

Can it withstand the erosion caused by a large amount of cow manure processing for a long time? Of course, we especially equip it with rubber lining and cleaning holes, which can greatly reduce the possibility of wall sticking and improve its corrosion resistance.

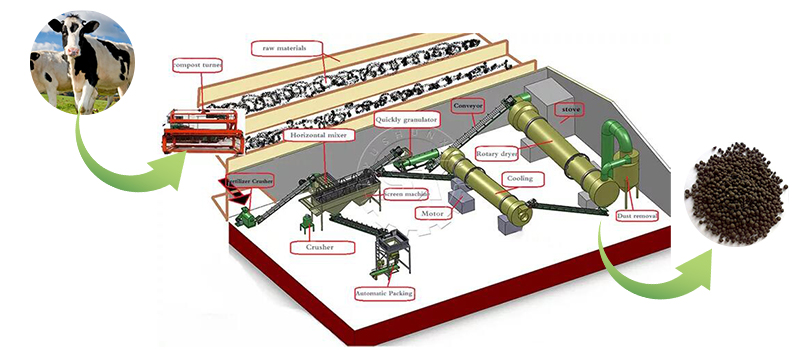

How to establish a cow manure fertilizer granulation line?

To start commercial cow manure pellets making and cattle waste fertilizer granulation plant setup more smoothly, it is necessary to establish a cow droppings fertilizer granulation line. So besides granulation equipment, you may need the following manure fertilizer processing machines.

What is the cost of your cattle waste granulation lines?

The price usually plays an important role in cow dung granulation line selection. Then in items of cost, our cattle manure fertilizer pellet systems can be divided into three parts:

$110,000 cow dung granulation line

If your budget for granular cow manure fertilizer manufacturing is lower than $110,000, disc granulator is the optimum option for you. And combing it with small compost machine, crusher, mixer, screener and bagging equipment, you can setup a cow manure granulation line with a low investment.

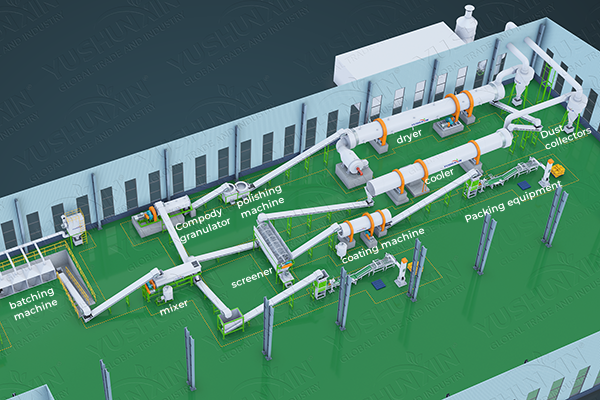

$110,000-$190,000 dairy waste pellet making line

But provided you have prepared $110,000-$190,000 for turning cattle droppings into granular organic fertilizer, we recommend you buy new type organic fertilizer granulation line. It can improve the quality of your organic fertilizer in appearance and hardness.

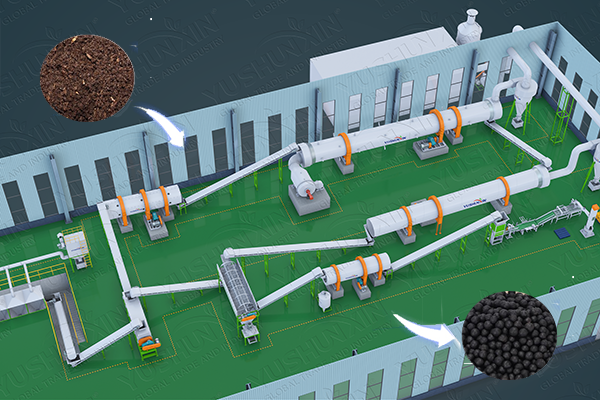

$190,000-$550,000 cattle manure granule production line

For those who plan to invest $190,000-$550,000 in cow manure fertilizer granulation plant, you can choose rotary drum pellet making line. It is the best choice to process a large amount of cow dung into pellets in a short time.

In addition, we also can provide you many other fertilizer granulation plans. Such as organic compost granulation system, NPK pellets making facility, chicken manure granulation plan, etc. Welcome to contact us for your own fertilizer business soluitions!