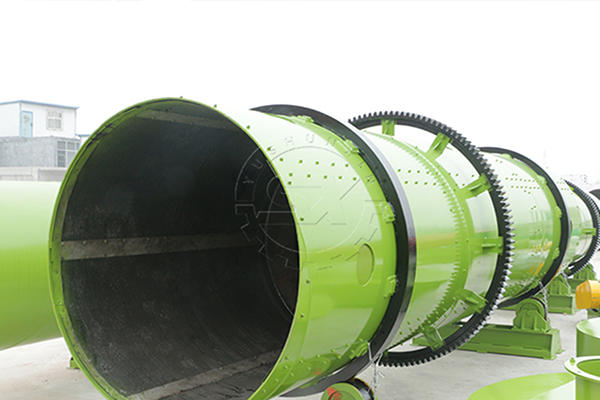

Are you looking for a granulator for large scale fertilizer production? Do you want to prepare large scale fertilizer pellets with low energy consumption? Rotary drum granulator can fully meet your requirements. It adopts wet granulation method, which uses liquid as binders to enhance the cohesive force between materials to turn fertilizer powder into granules. So it can help you make quality fertilizer. In addition, in order to produce fertilizer granules more smoothly, we especially upgrade its inside designs of reducing the possibility of wall sticking and improving the efficiency of granulation. Therefore, it can be used not only in compound fertilizer manufacturing but also organic fertilizer making. What’s more, combing with other fertilizer machines, it can help you set up a fertilizer granulation plant to make more profits!

What can rotary drum granulator do for your fertilizer pellet production?

Rotary drum pelletizer is widely used in granular fertilizer making, especially industrial NPK fertilizer granulation. Why? What can it do for your fertilizer pellet production?

Main Technical Parameters of Rotary Drum Granulator

| Model | Power (kw) | Diameter (mm) | Length (mm) | Installation Angle | Rotary Speed (r/min) | Capacity (t/h) |

|---|---|---|---|---|---|---|

| SXZGZ-1240 | 5.5 | 1200 | 4000 | 2-5° | 17 | 1-3 |

| SXZGZ-1560 | 11 | 1500 | 6000 | 2-5° | 17.5 | 3-5 |

| SXZGZ-1870 | 15 | 1800 | 7000 | 2-5° | 11.5 | 5-8 |

| SXZGZ-2080 | 18.5 | 2000 | 8000 | 2-5° | 11 | 8-15 |

| SXZGZ-3210 | 37 | 3200 | 10000 | 2-5° | 9.5 | 15-30 |

How does rotary drum rotary pelletizer work to granulate your fertilizer powder?

As mentioned above, rotary drum granulator employs the wet granulation method to turn fertilizer powder into granules. In the process of fertilizer powder granulation, it makes use of liquid cohesion to make the powder material ombine with each other and form into granules in 3-5 mins. In addition, with the driving of the main motor, the large gear will make the drum rotation, which is also beneficial for fertilizer pellet production.

How to granulate fertilizer powder with drum granulation equipment?

If you want to prepare fertilizer pellets better, you can inject steam to rotary drum granulation. For one thing, it can moisten the powder, creating a tacky surface for material to stick together in granules. For another, this raises the temperature inside the rotary drum granulator, which helps in quick solidification and binding of granules.

Through this process, whether you want to start large scale production of cold or hot granulation. Whether you plan to prepare high, medium or low concentration fertilizer particles. Rotary drum pelletizer can meet your needs.

3 Designs of drum granulator make you produce better fertilizer granules

In the process of large scale fertilizer granulation, there is an item most fertilizer manufacturers focus on. Because of wet granulation, the materials are easy to stick to the wall. This will affect the granulation efficiency of rotary drum fertilizer pellet production and cause serious erosion to the granulator. For this, we especially upgrade the designs as follows:

Rubber lining

To make granulation equipment withstand the erosion of large scale compound fertilizer processing, one best way is improving the corrosion resistance. On the basis of using Q235B boiler steel to produce the rotary drum pelletizer, we equipment it with a rubber lining. Therefore, this granulation equipment has better erosion resistance and a longer service life.

Stainless press stripes

In order to improve the corrosion resistance of rotary drum pellet making equipment, we adopts stainless steel press strips on rubber lining equipment. They can firmly fix the lining to the inner wall of drum pellet making machine and have high erosion resistance because of using stainless steel as materials.

Cleaning holes

But after a long time running, there are still some materials sticking to the inner wall. And the granulation efficiency will be affected. Then how treat those sticking materials? You can clean them up with special holes. Using harmmers to knock those cleaning holes. The materials will fall under the action of vibration.

Can rotary drum granulator process manure compost into fertilizer pellets?

From the above introduction, we know that rotary drum granulation machine is an excellent choice for large scale compound fertilizer manufacturing (including NPK fertilizer production and phosphate fertilizer preparing). But, is it suitable for organic fertilizer granule making? The answer is yes. It has a high performance in anti-corrosion. So even using it to granulate a large amount of manure compost, it can complete this task quickly and easily.

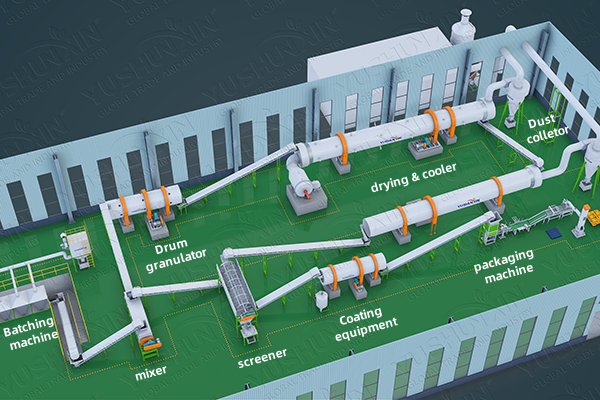

How to setup a fertilizer drum granulation plant?

If you want to setup a rotary drum granulation plant, buying drum pelletizer only is not enough. It is necessary to choose other fertilizer processing machines to establish a professional fertilizer granulation line. In this process, cost and factory area are two items you must pay attention to. So to establish a rotary drum fertilizer granulation factory, you need to do the following things:

What equipment is needed in a rotary fertilizer granulation line?

When you plan to create a compound fertilizer granulation line, besides rotary drum granulator, you also need to buy batching machine, crusher, mixer, screener, dryer, cooler, dust collector, dust fall room, coating equipment and belt conveyor. When it comes to organic fertilizer granulation line, you may also need to purchase fertilizer dehydrator and large compost machine.

How much does a rotary fertilizer granulation plant setup cost?

Cost also plays an important role in rotary drum granulation plant setup. It contains the costs of equipment, workshop building, energy consumption, worker employment, etc. Then because our rotary drum granulation system has characteristics of low energy consumption and high automation. And as a source factory of fertilizer equipment, SX can provide you with equipment at a favourable price. You can setup the rotary drum granulation plant at a low cost.

What is the area occupation of a rotary fertilizer pellet making system?

The area occupation also will vary according to the capacity and configuration. Generally, a 5 t/h rotary drum granulation line needs an area of 3,000-4,500 ㎡. And you need to prepare a 5,500-10,000 ㎡site for a 20 t/h drum pellet making system installation.

If you have any other want know about rotary drum granulator for fertilizer making or get your customized fertilizer manfuacturing plan, welcome to contact us now!