For biogas project working, most businesses will start an organic fertilizer production line as an auxiliary project. Because it can dispose of biogas production waste into commercial products quickly. This is beneficial for not only eliminating biogas making waste but also increasing your income. On 25th August 2023, a biogas production company from India inquired about how to make pellets from cow dung compost? The following are the specific details of our communication in this case:

What does the Indian customer want to do with cow dung compost?

Characteristics

Solid waste Generated – 30 TPD

Moisture – 70%

Solids/DM (dry matter)- 30%

How to remove the excessive water from cow manure compost for pellets making?

No matter what fertilizer you want to produce, material is important. The same as cow dung compost granules making. In this process, besides organic material type, you also need to focus on the moisture content. From the Indian client’s introduction, the compost material has a water content of 70% and solids/DM of 30%. But for making pellets from cow dung, we mainly use solid matter materials. And before cattle manure granulation, it is advisable to adjust the water content to about 30%-40%. So cow dung compost materials can combine with each other and form into organic fertilizer granules quickly.

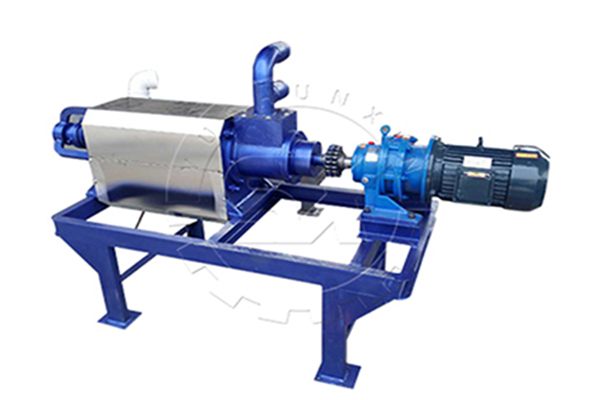

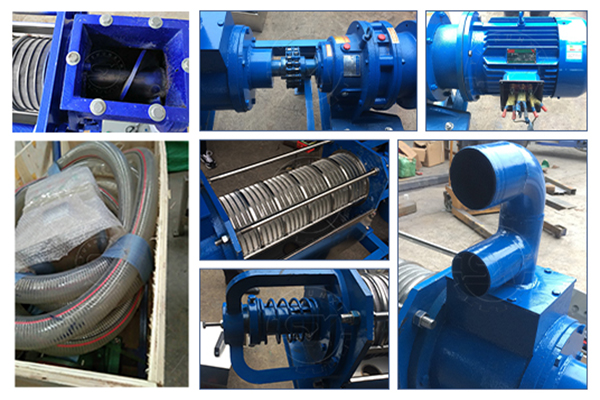

Then how to reduce the moisture content of the Indian customer’s compost material? For 70% water content material, we recommend you choose a screw type manure dehydrator. Making use of screw rotation and screen filter, it can reduce the moisture of cow manure compost to 30% in several minutes.

How to setup a complete 30 t/d system for making pellets from cow dung compost?

Differ from others, the customer from India had clear goals. He had ensued what equipment is contained in the cow waste pellets making line. The client wanted to setup an organic fertilizer granulation line, which consists of crushing unit, mixing unit, granulating unit, drying unit, cooling unit and packaging unit. But the Indian client is still hesitant about which equipment is suitable for processing the 30 Tonnes of solid cow manure compost into pellets?

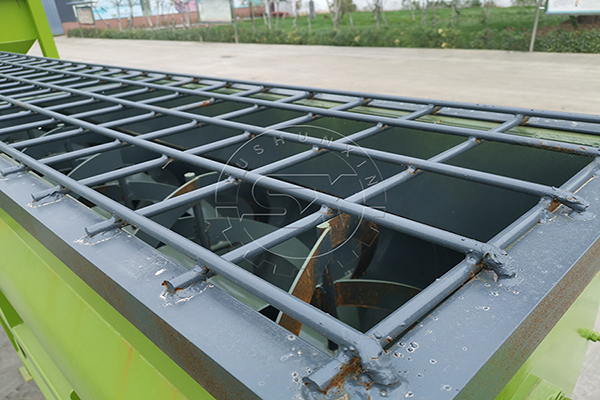

Here, SX can offer you the best solution according to your actual conditions. Because the water content of manure compost is 70%, you can get 15-20 tons of suitable materials for organic fertilizer pellets manufacturing a day. In addition, the advisable working time of organic fertilizer equipment is below 20 hours a day. Therefore, the client needs organic fertilizer pellet making machines with a capacity of 1-2 t/h. For this, you can setup a manure fertilizer granulation line with these machines: SXSF-40 semi-wet crusher, SXDJ-1050 single shaft mixer, SXYZ-2500 pan pelletizer, SXHG-0808 rotary dryer, SXLQ-0808 rotary cooler and single bucket automatic packaging machine.

Technology parameters of the 30 t/day cow manure compost pellet making line

|

Equipment |

Model | Capacity(t/h) | Feed / discharge material moisture | Power (kw) | Dimension (mm) |

|---|---|---|---|---|---|

|

Screw type dehydrator |

2-3 |

50%-80% |

|||

|

Semi-wet materials crusher |

SXSF-40 | 1-1.5 | 25%-55% | 22 |

1200×1350×900 |

|

Single shaft mixer |

SXDJ-1050 | 2-3 | 11 |

3700×800×750 |

|

| Pan pelletizer | SXYZ-2500 | 1.5-2 | 30%-45% | 7.5 |

2900×2000×2750 |

|

Rotary dryer |

SXHG-0808 | 1-2 | 5%-10% | 5.5 | |

|

Rotary cooler |

SXLQ-0808 | 1-2 | 5%-10% | 5.5 | |

| Single bucket packaging scale | Below 10% |

The above are details about our communication with the customer about how to make pellets from cow dung compost in India. In addition, we also have other organic fertilizer making plans for your choice. Such as chicken manure organic fertilizer production system, pig manure management plan, horse manure as fertilizer method, etc.