Fertilizer blending plant is set up to produce compound fertilizer by mixing several chemical granules evenly in proportion. This type of fertilizer is often referred to as bulk blending fertilizer production, abbreviated as BB fertilizer. Usually, its nutrient proportion is not fixed and can be adjusted according to local farming conditions. So more and more fertilizer manufacturers prefer to invest in bulk blending fertilizer production. For this, YUSHUNXIN, as a professional fertilizer machine factory, can provide proposals in many aspects. Including material selection, factory location, business plan choosing, etc.

How to prepare materials for fertilizer blending plant setup?

When you want to start bulk blending fertilizer making, materials preparation is an item you must focus on. Then what is the principle of BB fertilizer production materials selection? Generally, you need to pay attention to three principles:

Chemical materials

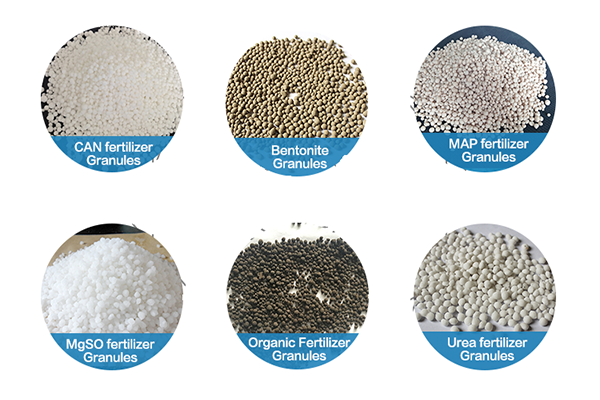

Bulk blending fertilizer is a kind of compound fertilizer. So the raw materials of it are commonly various single chemical fertilizers or complex fertilizers. Such as urea, gypsum, DAP, TSP, ammonium sulphate, etc.

Uniform granules size

In general, fertilizer blending plant is built to process granular chemical materials into required fertilizer. It is the premise of using chemical fertilizer pellets for starting BB fertilizer making. In addition, in order to prepare high quality bulk blending fertilizer, it is advisable to choose granules with uniform size. Otherwise, the even fertilizer nutrient is easy to layer during transport. Then it will affect the nutrient supply for the growth of crops.

No chemical reaction

Finally, you’d better select materials which have no chemical reaction. Because chemical reaction is a process that leads to the chemical transformation of one set of chemical substances to another. This will change the nutrient proportion of fertilizer and even generate harmful substances.

What equipment is needed in bulk blending fertilizer manufacturing?

Besides suitable material election, it is also necessary to buy professional equipment for fertilizer blending plant. Because it is the secret of finishing bulk blending fertilizer smoothly and quickly. But what machine is needed for BB fertilizer production? In general, you need the following four fertilizer processing machines.

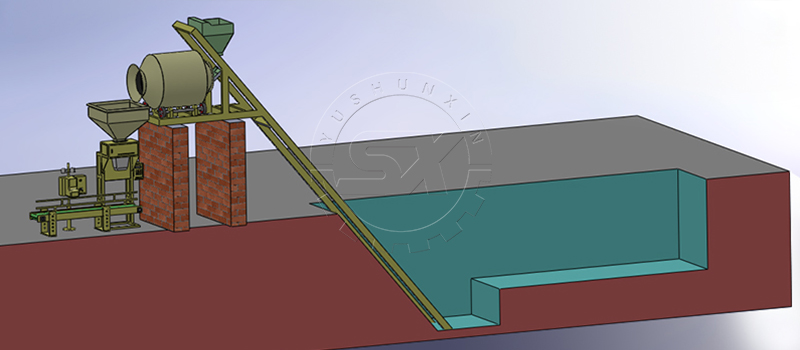

Batching machine

As mentioned above, BB fertilizer is a mixture of a variety of chemical materials with a certain proportion. If the proportion is changed, the final fertilizer will no longer be suitable for local farming conditions and even cause damage to it. But how to ensure that you can make BB fertilizer strictly according to the formula proportion? Using batching machine, which adopts an electrical weighting system and feeds different chemical materials in order instead of all at once. Therefore, it can feed required materials with high precision.

BB fertilizer mixer

Bulk blending fertilizer making, as the name suggests, mixing machine plays an important role in this process. For this, we especially design professional BB fertilizer mixer. It overcomes the mixtures chromatography and distributaries phenomena caused by different proportions of raw materials and particle size. Moreover, it also solves the influence of material properties, mechanical vibration, air pressure, etc. So it can help you blend various chemical materials evenly to ensure the nutrient balance of your BB fertilizer.

Automatic packaging machine

After mixing, you can package the compound fertilizer directly. What a simple process! Then to finish blending fertilizer faster, we recommend you buy an automatic bagging machine. It has an electrically automatic weighting system, which has a quantitative precision of 2‰. Therefore, it can help you pack final BB fertilizer into 10 kg, 25 kg, 50 kg, etc in a short time. In this way, you can transport, store and sell them more conveniently.

Top 2 business plans for BB fertilizer production

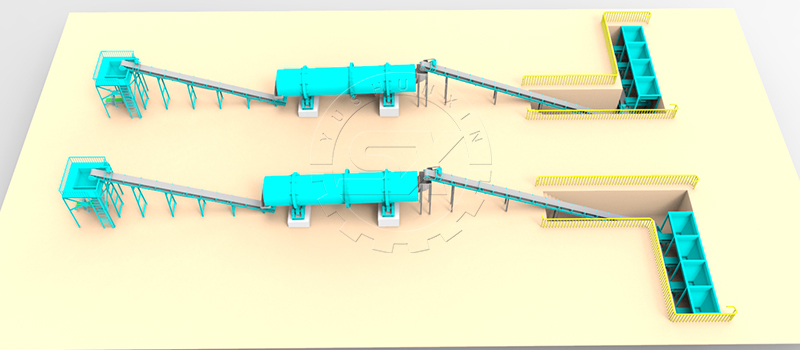

In order to different requirements of fertilizer suppliers, we especially design fertilizer blending business plans with different capacities. One is designed for small scale compound fertilizer making plants, which need to produce 5-10 tons of BB fertilizer per hour. Another one is rotary drum mixing fertilizer line, which is suitable for preparing bulk blending fertilizer in a large scale.

How to choose an area for fertilizer blending plant setup?

After material collection and equipment purchasing, you also need to prepare a suitable place for fertilizer blending plant establishing. Usually, you need to pay attention to two items

For one thing, you’d better start BB fertilizer preparation close to raw material origin. For another, it is advisable to build fertilizer blending plant in places with convenient transportation. Then it is easy to transport material back to the factory and deliver compound fertilizer products to customers.

Generally, only needs a 100-900 ㎡ of site, bulk blending fertilizer manufacturing line can help you finish the chemical fertilizer making of 5-80 t/h easily.

Can fertilizer blending line produce NPK fertilizer?

NPK blending system cases

YUSHUNXIN blended fertilizer line have help many manufacturers in the world start their compound NPK fertilizer production plants. Such as 10 TPH bulk blending fertilizer line in Myanmar, 20-30 T/H BB fertilizer making plant setup in Nigeria, 100 tons per day blended NPK fertilizer makng system in Sri Lanka, etc for your reference.

In addition, if you want to make other compound NPK fertilizer, there are also various designs for your choice. Including NPK powder granulation line, SSP phosphate fertilizer production plan and other mineral material fertilizer making projects, etc. Welcome to contact us to get them now!