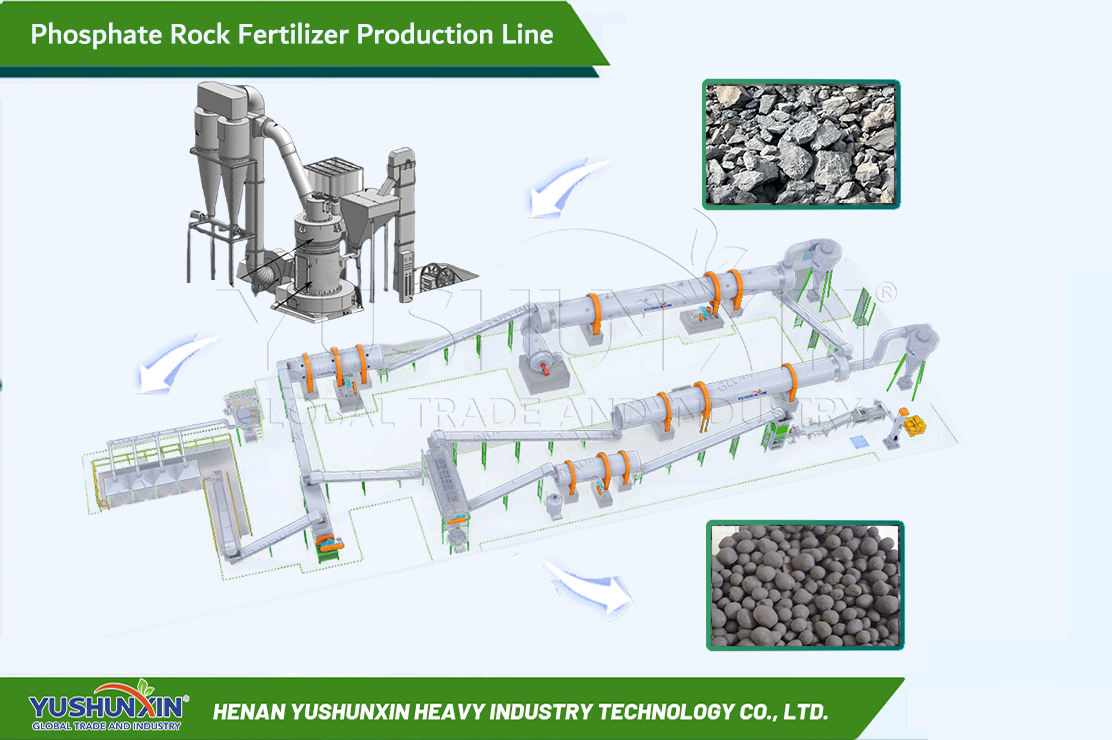

In NPK fertilizer making, SSP Phosphate fertilizer production is favoured by a large amount of fertilizer manufacturers. Because it contains rich phosphorus elements, which plays an important role in the germination and fruiting of plants. But how to make SSP compound fertilizer? Mainly using SSP rocks and concentrated sulfuric acid/nitric acid as material, crushing, mixing, acidification, aging, grinding again, screening and packaging. In addition, you also choose to further process it in SSP granules. Finally, don’t forget to filter gas waste to meet local environmental requirements.

How to process SSP rocks for phosphate fertilizer production?

The main materials of SSP phosphate fertilizer production are SSP rocks, concentrated sulfuric acid/nitric acid. However, it is unwise to directly use them to prepare the required phosphate fertilizer. There are some necessary processes needed.

Crushing phosphate rocks into fine powder

Due to better SSP compound fertilizer manufacturing, it is advisable to crush phosphate rocks in powder first. For one thing, SSP powder can fully commingle with liquid acid material. For another, powdery material is greatly beneficial for phosphate fertilizer pellets making. Here, we recommend to use jaw crusher to break rocks into small particles. Then Raymond mill is an excellent choice to further grind small SSP particles into fine powder.

Mixing with sulfuric acid/nitric acid

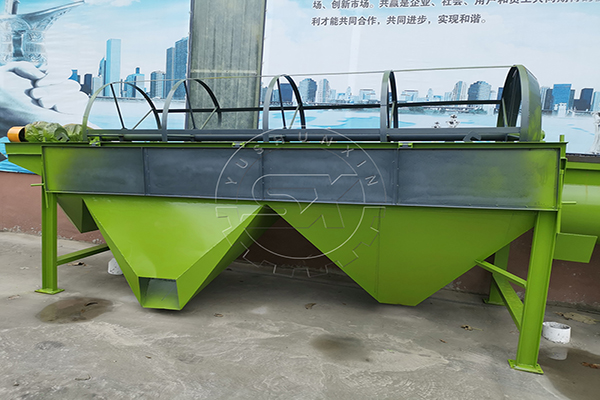

Besides phosphate rocks, concentrated sulfuric acid/nitric acid is also the important material for making SSP phosphate fertilizer. Therefore, in order to produce quality phosphate fertilizer, it is necessary to mix SSP rock powder with concentrated sulfuric acid/nitric acid evenly. For this, we can provide you with suitable fertilizer blending equipment. Small scale, large scale, disc vertical and various horizontal mixers.

Acidification and aging

Then you need to transport the mixture of phosphate rock powder and acid to a closed room. In this room, it will fully react and form into the material you need. This process is called acidification and it generally takes 3-4 hours. Is it the end? No. Because of blending of phosphate rock powder and liquid acid, acidified SSP material has a moisture of 50%-60%, which cannot meet the requirements of further processing. Therefore, you need to aging the SSP + acid materials after acidification.

If you have no plan to make granular SSP fertilizer, only need three steps, you can sell finished powdery phosphate fertilizer to your customers. Crushing, sieving and packaging. As a professional fertilizer equipment factory, YUSHUNXIN can offer you an ideal SSP powder fertilizer making plan.

What is the process of SSP granule fertilizer manufacturing?

However, if you want to manufacture SSP fertilizer granules, after aging, you need to take the following steps:

Grinding aged material

Before starting SSP granule fertilizer manufacturing, it is necessary to shred aged chemical materials again. Because the material particle size is closely related to chemical fertilizer granulation effect. The finer the material powder, the easier the SSP pellets making, the more beautiful the pellet appearance. But because you mix the phosphate rock powder with concentrated sulfuric acid/nitric acid (liquid), the aged SSP materials will have many agglomerates. So you need to make it into fine powder with a suitable crusher.

SSP granulation

The you can take the most important step – SSP phosphate fertilizer granulation. Here are three types of compound NPK fertilizer granulator that are recommended to you. When you only start a small scale SSP fertilizer granulation, it is advisable to buy pan pelletizer, whose capacity is 1-6 t/h. However, for large scale SSP fertilizer pellets making, drum granulator is the most suitable one. Because it has a large output of 1-30 t/h, you can finish large scale chemical fertilizer granules manufacturing effectively. Is there a lower cost phosphate fertilizer granulation plan? Of course. Double roller granulator is designed for you. It adopts dry granulation method, so you can save money on drying and cooling.

Screening

One standard of quality granular fertilizer making is uniform size. But there is no equipment that has a 100% granulation rate of required SSP size pellets. Then how to sieve out the required chemical granule, which can enter the next process? Granule rotary screener is here! Galvanized steel mesh can divide phosphate fertilizer balls into small size, required size and large size. After screening, you can return small and large size pellets to crush and granulation again.

Drying and cooling

As mentioned above, double roller dry granulation doesn’t need subsequent drying and cooling. However, they are necessary for disc and rotary drum granulations of SSP material. The reason is that after wet granulation, the moisture content of fertilizer pellet is about 20%. It is not high, but still does not meet the requirements of long time storage. So you need to add dryer and cooler after pan pelletizer and drum granulator.

Packaging

In general, this is the end of an SSP phosphate fertilizer production line. Pakckaged fertilizer is more convenient for storage, transport and use. For this process, SX also can provide you with professional automatic bagging equipment, which has a quantitative precision of 2 ‰. This machine can help you pack finished SSP fertilizer pellets into bags quickly.

How to dispose of gas waste generated by SSP phosphate fertilizer production?

Related phosphorus fertilizer making case in the world

In the past 20 years, YUSHUXIN have help many SSP phosphorus fertilizer manufacturers start their business. They are from Romania, Morocco, Colombia, Pakistan, Iran, Egypt,etc. There are some examples for your reference. Such as 200TPD Granular Phosphate Fertilizer Manufacturing In Morocco, 30 t/h Phosphate Compound Fertilizer Granulation Line in Romania, etc

Besides, phosphate rocks to fetilizer plan, we also can provide you with many other mine waste fertilizer making systems. Such as limestone fertilizer production line, zeolite granulation plan, etc. Welcome to contact us for your own fertilizer business plan immediately.