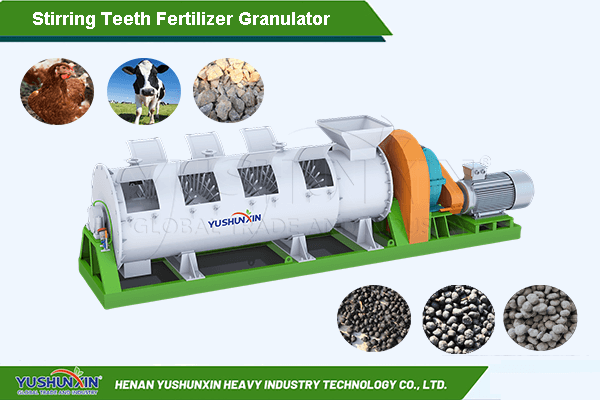

Stirring teeth granular fertilizer machine, also called new type organic fertilizer granulator, is a crucial kind of equipment in the production of granular fertilizers. Widely used for processing both organic and complex fertilizers. This machine helps transform raw materials into uniform pellets of high harness, 2-5 mm size, round shape, etc. Additionally, whether you need a fertilizer granule making solution with $200,000 cost or $50,000 investment, there are customized business plans for you.

What kind of fertilizer pellets can stirring teeth granular fertilizer machine process?

One of the standout features of the stirring teeth granular fertilizer machine is its ability to make popular fertilizer pellets with high hardness, 2-5 mm size and round shape.

High hardness granular fertilizer making

One of the key advantages of the new type organic fertilizer granulation equipment is its ability to create fertilizer pellets with high hardness. This can reduce the efficacy loss during transportation or storage. Here, stirring teeth pelletizer mainly makes use of the friction between teeth and body to turn powder into granular fertilizer. Because of mechanical press force involved, the granulated fertilizer has high hardness.

Adjustable 2-5 mm size fertilizer production

Moreover, for pelletized fertilizer size, the machine can fully meet your requirements of 2-5 mm fertilizer pellet manufacturing. This is also commonly used by farmers. How to regulate the fertilizer pellet size during stirring teeth granulation? By moisture control and stirring teeth rotation speed adjustment. The more the water, the larger the size; the less the water, the smaller the size. The slower the speed, the larger the size; the faster the speed, the smaller the size.

Round ball fertilizer pellet manufacturing

As for the final fertilizer shape, the stirring teeth granular fertilizer granulator will offer round balls fertilizer for you. Round-shaped pellets are often preferred because they have better flow characteristics during spreading. So, you can produce fertilizer with a high competitiveness. Can we make the stirring teeth granulation fertilizer more rounded? Of course, there is fertilizer polishing machine in YUSHUNXIN for you.

| Model | Capacity (T/H) | Powder (kw) | Feed Moisrure | Feed Size (mesh) | Dimensions (mm) |

|---|---|---|---|---|---|

| SXJZ-600 | 1-1.5 | 37 | 20%-40% | 50 | 4900x2550x1800 |

| SXJZ-800 | 1.5-2.5 | 55 | 20%-40% | 50 | 5500x2800x2000 |

| SXJZ-1000 | 2-4 | 75 | 20%-40% | 50 | 4100x1600x1130 |

| SXJZ-1200 | 4-6 | 90 | 20%-40% | 50 | 4250x1850x1300 |

| SXJZ-1500 | 6-8 | 110 | 20%-40% | 50 | 4700x2350x1600 |

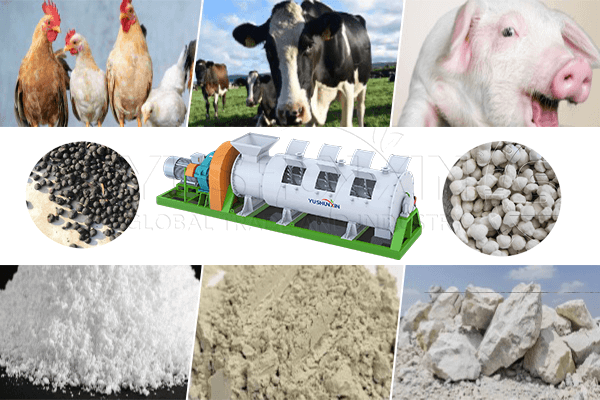

Can the stirring teeth granulator produce organic fertilizer?

Yes. This equipment is also called new type organic fertilizer granulator. It is especially designed for produce fertilizer pellets from organic waste.

This makes it an excellent choice for organic fertilizer producers looking to improve their production efficiency while maintaining the integrity of the raw materials. In addition, if you want to process pellet from power of complex material, like NPK, zeolite, limestone, etc, there are also customized stirring teeth pellet equipment for you. Welcome to see it immediately!

Can we set up a 30,000 tpy organic fertilizer granulation plant with the new-type fertilizer pelletizer?

The answer is yes. In general, with 5 models, the stirring teeth pellet machine can produce granular organic fertilizer of 1-8 tons per hour. If you setup a organic fertilizer granulation plant, which works 2 shifts a day and 10 hour a shift, the maximum annual output can reach 48,000 tons. Therefore, it is absolutely possible to build a 30,000 tons per year organic fertilizer granulation plant with the new type of pelletizer. Buy the model of SXJZ-1200 (4-6 TPH capacity) is enough.

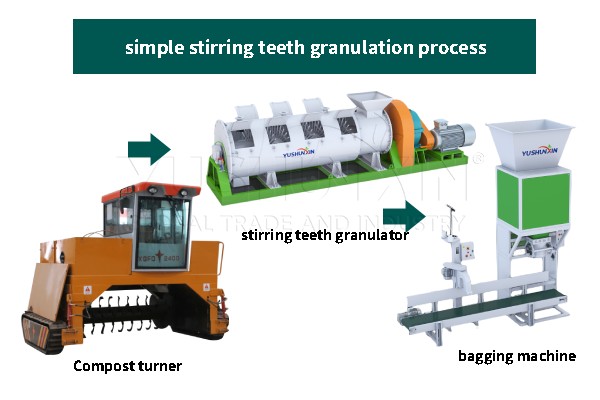

Can we start granular fertilizer making by only the stirring teeth granular fertilizer machine?

Of course. The configuration of a stirring teeth fertilizer granulation line is flexible.

For industrial granular fertilizer making project, you can choose to buy complete stirring tooth pelletizing system for you. At the same time, there are also simple solutions for you. Such as compost machine + new type organic fertilizer granulator + bagging machine, or only a stirring teeth granulation equipment. You can deciding it according to your area, budget, capacity, etc.

How long does it take to replace the stirring teeth for fertilizer pellet making effectively?

Maintaining the stirring teeth granular fertilizer machine is essential for ensuring consistent performance. Over time, the stirring teeth may wear out due to the continuous mechanical action involved in pelletizing fertilizer materials. Replacing the stirring teeth is crucial to maintaining the efficiency of the granulator and preventing any issues related to pellet quality.

When replacement is needed, the process is relatively simple. The skilled workers can usually replace the stirring teeth within just a few hours. And you can buy the parts locally. By performing regular inspections and replacing worn teeth on time,you can produce fertilizer pellets with consistent quality.

If you want to get more information or inquiry other fertilizer granulation machines, welcome to contact us now! There are customized fertilizer business plan and solutions for you. Also, economical disc pelletizer, no drying roller extrusion granulator, industrial drum granulation machine, etc here.