Many fertilizer manufacturers ask if there is a solution to produce powder and granular fertilizers at the same time. Because the market demands are diverse, some customers prefer powder fertilizer for quick soil absorption, while others require granular fertilizer for easier application and longer storage. With the reasonable design, YUSHUNXIN can help you produce fertilizer in both forms within a system. This is an ideal choice for you to expand the fertilizer making business opportunities and reduce investment costs.

Why combine powder and granule fertilizer production?

Farmers and distributors often need different fertilizer forms for different crops and soil conditions. Powder fertilizers dissolve fast in water and work well for foliar spraying, but granules release nutrients slowly and suit large-scale field application.

If you can produce powder and granular fertilizers together, you can meet wider customer needs without building two separate plants. Because you only invest in a fertilizer making line, you reduce the cost compared to building two separate systems of powder fertilizer making and granular fertilizer manufacturing. Moreover, you can respond quickly to market changes, there is a higher flexibility and profitability.

How does the powder and granular fertilizer making process work?

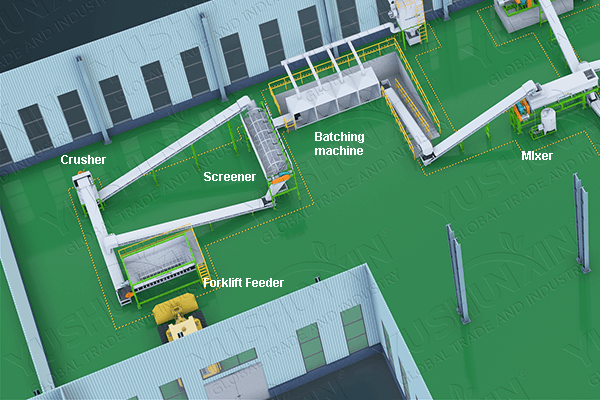

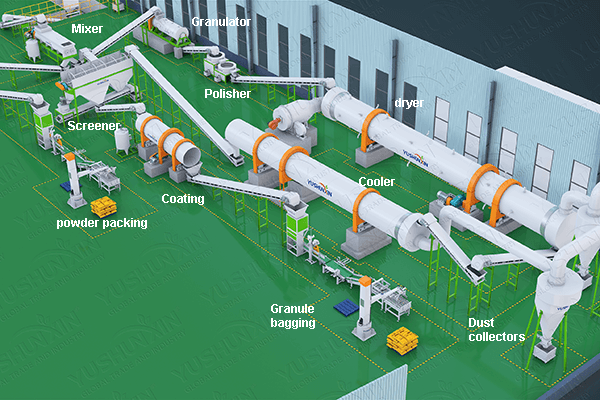

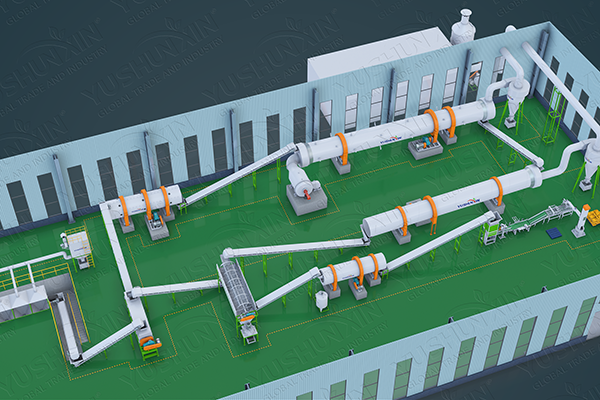

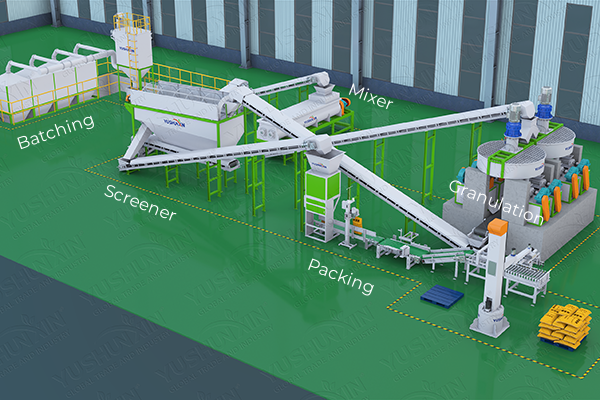

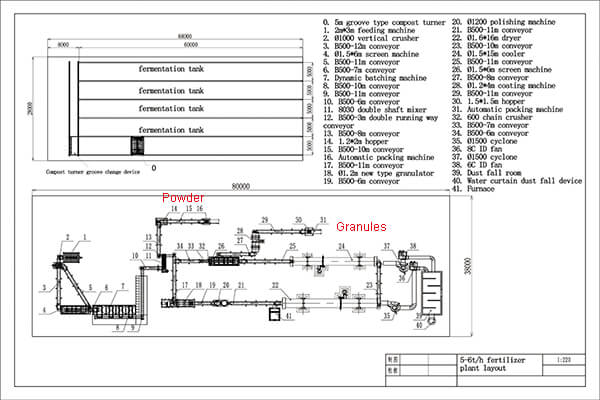

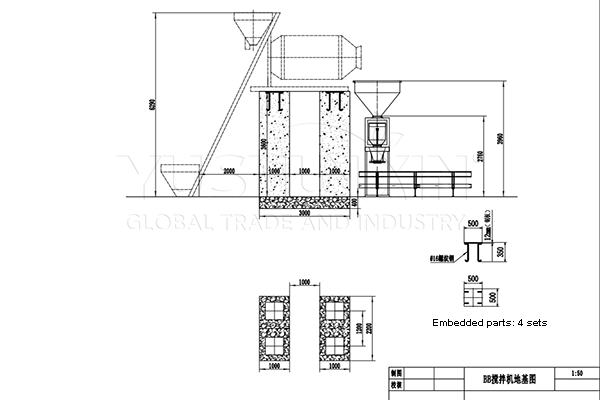

The key is the reasonable design. Here, our engineers divide the system to make powder and granule fertilizer into 3 parts.

What equipment do you need for the two-in-one fertilizer making system?

What equipment is needed to produce powder and granular fertilizers simultaneously? Here, take the organic fertilizer manufacturing system as a example. It needs the following fertilizer machines.

As for complex fertilizer production with powder and granule simultaneously, it only needs from batching equipment, powder grinder, powder screener, mixer, powder bagging machine, compound granulator, granule sieving machine, dryer, cooler and pellet packing scale.

How about the area covered the multifunctional fertilizer manufacturing system?

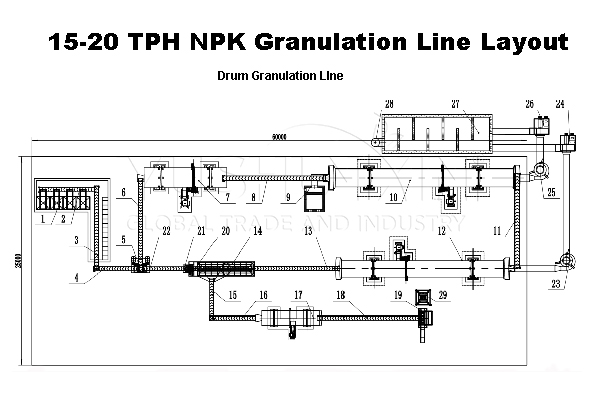

When planning a multifunctional fertilizer manufacturing system, understanding the space requirements is essential for smooth operation and future expansion. The area needed by the fertilizer making system, largely depends on its capacity, which typically ranges from 1 to 30 tons per hour (TPH).

| Capacity (TPH) | Area Needed (㎡) |

|---|---|

| 1-2 | 1500-2000 |

| 3 | 3000 |

| 5 | 4500 |

| 10 | 5500 |

| 20 | 10000 |

| 30 | 14000 |

There is also many other practical solutions to produce powder and granular fertilizers simultaneously in YUSHUNXIN. This approach helps you maximize resources, lower costs, and meet diverse agricultural needs. Welcome to get it now!