NPK 20-20-20 fertilizer making is a project many manufacturers invest in. It is balanced formulation for making fertilizer with nitrogen (N), phosphorus (P), and potassium (K) elements. In general, there are two main solutions to make NPK fertilizer 20-20-20. NPK powder granulation line and NPK granules blending system. Here, YUSHUNXIN especially design quality batching machines and mixers. They can ensure the precise proportion feeding and balanced nutrient distribution of final produced NPK fertilizer.

Top 2 solutions to make NPK fertilizer 20-20-20

To making NPK fertilizer 20-20-20, there are 2 solutions commonly used by manufacturers.

NPK powder granulation line

If you have a enough budget for 20-20-20 NPK fertilizer manufacturing, the best solution is processing NPK powder into granules. With intricate procedures, the produced NPK fertilizer has a high value because of stable nutrient contained and lower possibility of nutrient layering.

NPK granules blending system

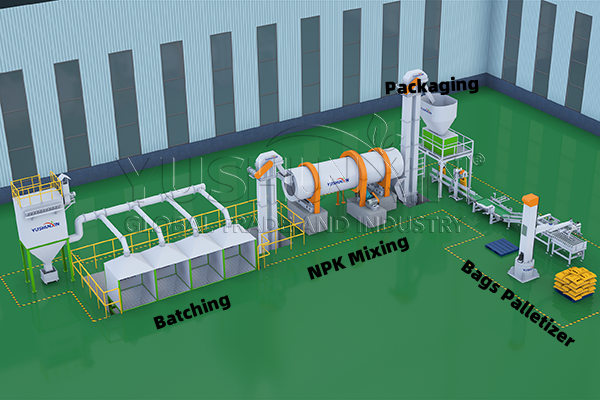

For those who has a investment limited in NPK 20-20-20 fertilizer making. You can choose to buy a fertilizer granules blending system, which also known as BB (bulk blending) fertilizer production line.

This solution is a simpler and more cost-effective method for preparing 20-20-20 NPK fertilizer. Only $20,000- $190,000, you can finish the 1-40 t/h output. The system will make NPK fertilizer 20-20-20 by mixing already-granulated nitrogen, phosphorus, and potassium fertilizers in the correct ratio. It usually contains machines of automatic batching machine, BB fertilizer mixer, and packaging equipment.

How to ensure the produced NPK fertilizer strictly in 20-20-20 proportion?

The key to producing effective NPK 20-20-20 fertilizer lies in the precision of ingredient dosing and the uniformity of mixing. Here, we can offer you advanced fertilizer machines for both two steps.

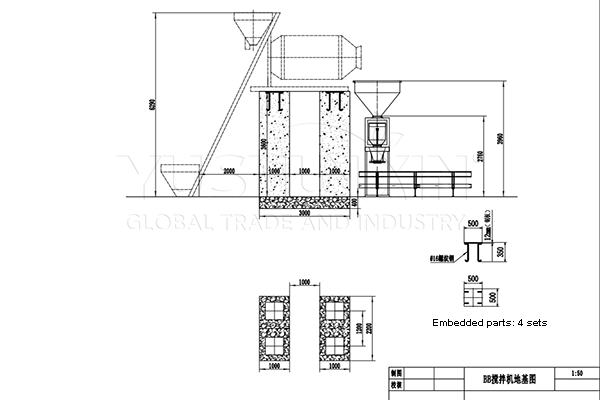

High-Precision batching machine

YUSHUNXIN batching equipment has high precision for NPK material feeding. Because it adopts advanced sensors and control panels to measure and feed raw materials accurately, minimizing error (lower than 0.5%) and ensuring the nutrient proportion is inline with your formula (20-20-20).

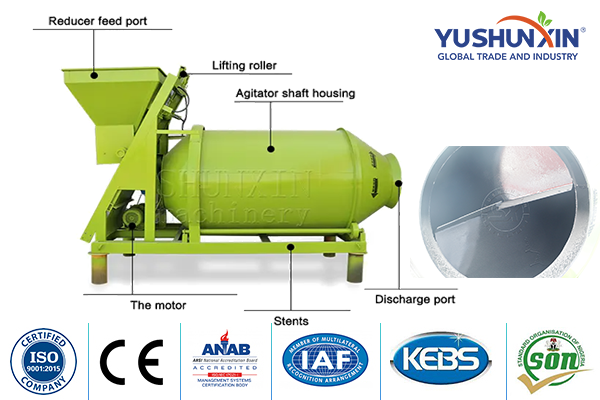

Evenly mixing equipment

At the same time, uniform mixing of N, P, K material is also critical to ensure balanced nutrient distribution. Generally, a professional fertilizer mixer is better than manual blending.

If you have any other questions about NPK fertilizer making, including 20-20-20 or 15 12 24, 10 20 10, etc, welcome to contact us immediately. As a professional fertilizer business plan and machine manufacturer, YUSHUNXIN will offer your the best solutions.