Are you finding solutions to organic waste disposal? Do you want to know what organic fertilizer business plans are available for you? Do you want to buy quality machines for your organic fertilizer production project? You can find answers from YUSHUNXIN. As a professional fertilizer equipment factory, we has advanced technology and years experience in organic fertilizer machines manufacturing. Besides quality organic fertilizer equipment, we also can provide you with various business plans for organic fertilizer making. In addition, if you have any requirements, you can contact us for customization. We will try our best to help you start the organic fertilizer production project smoothly!

How to make organic fertilizer into powder or granular?

In general, most organic fertilizer manufacturers prefer to prepare organic fertilizer into 2 forms. Powdery and granular. The former has a lower cost and fast investment return while the latter has a higher profits. But, no matter you want to start a powder or granular organic fertilizer produstion, YUSHUNXIN can provide you with the best solution.

Powdery organic fertilizer making system design

Powdery organic fertilizer manufacturing line is a simple process to make organic waste into fertilizer. So only needs a few fertilizer machines, it can help you finish commercial organic fertilizer making quickly. Including dehydrator, composting machine, loader type feeder, organic waste crusher, powder screener, powder packaging machine and belt conveyor.

Can powder fertilizer make system produce organic fertilizer in a large scale

Of course. The largest capacity of YUSHUNXIN powder organic fertilizer making line can reach 20 t/h or more. But it has characteristics of lower investment, less area occupation, high automation, etc. Therefore, it is a hot selling product for customers those who start organic fertilizer manufacturing initially. You can earn back your investment within one year, even shorten time.

Granular organic fertilizer production project technology

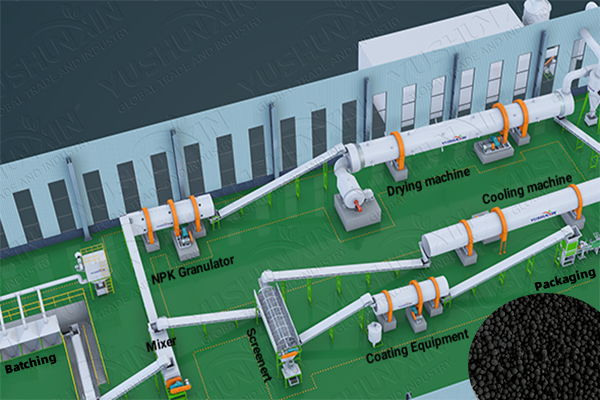

When you want to further process organic fertilizer, you can choose to turn powder compost organic fertilizer into granules. Then because of more complicated process, it needs more organic fertilizer machines. Generally, a complete granular organic fertilizer preparation line contains dehydrator, compost equipment, batching machine, crusher, mixer, granulator, screening equipment, dryer, cooler, coating machine, packaging machine, belt conveyor, dust collector. You can choose them to design your own plan for organic fertilizer production project according to your needs.

Does granular organic fertilizer making line need a large investment

Don’t worry, we can design organic fertilizer making line according to your budget. Moreover, the feedback from our past customers showed that they usually make profits in a short time.

How to start a 1-5 t/h small scale organic fertilizer production project?

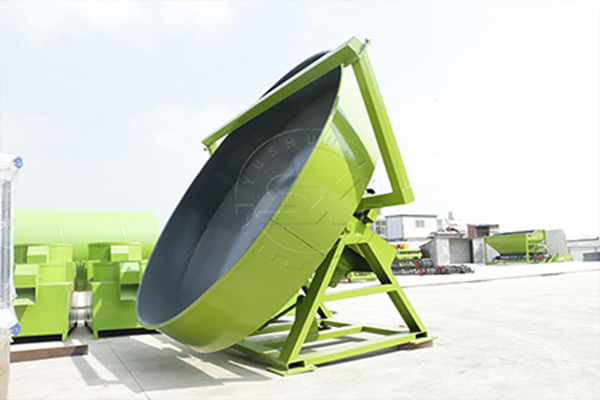

If you need a plan for turn organic waste into fertilizer in a small scale, which is about 1-5 t/h. Disc granulation line is an ideal choice for you. For one thing, it can fully meet your requirement to prepare 1-5 tons of organic fertilizer per hour. For another, it also has characteristics of high granulation rate (over 93%), low cost, high automation, less space occupation, etc. These can help you start small scale organic fertilizer production more smoothly.

What fertilizer machine is needed in disc granulation system

For running disc pan granulation line, you need to buy organic fertilizer machines of windrow compost turner, static batching machine, SXSF-120 semi-wet material crusher, double shafts horizontal mixer, SXYZ-3600 disc granulator, SXGS-1240 rotary screener, SXHG-1515 rotary dryer, SXLQ-1515 rotary cooler, BM1400×4000 coating machine, automatic bagging machine and so on.

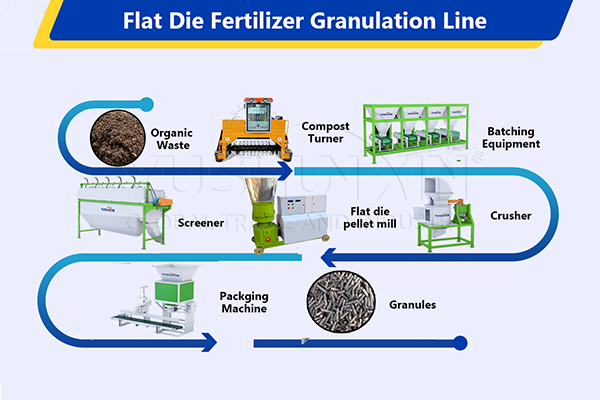

Is there a more compact organic fertilizer granulation line?

Of course. For making organic fertilizer in a smaller area, you also can choose our flat die dry granulation line. It adopts dry granulation method, which relies on physical force between roller and mold to granulate organic fertilizer. There is nearly no water involved, so it is dispensable to buy dryer and cooler. In this way, you can spend less and don’t need to prepare a large installation area.

| Equipment | Capacity (T/H) | Feeding Moisture | Granule Size (mm) | Pellet Shape |

|---|---|---|---|---|

| Disc Granulator | 1-6 | 20%-40% | 1-8 | Round ball |

| Flat Pellet Mill | 1-2.5 | <15% | 2-10 | Column |

What is the design of a 5-8 T/H organic fertilizer production line?

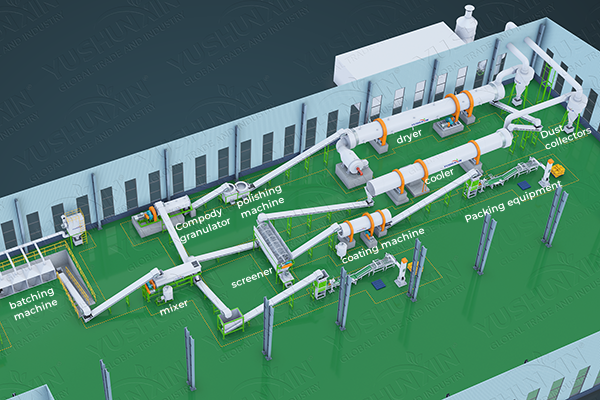

However, when you want to produce 5-10 tons of organic fertilizer per hour, stirring teeth granulation line is more suitable for you. Besides the suitable capacity, it also can help you produce organic fertilizer pellets with a higher hardness. Moreover, it is a fully automatic organic fertilizer making system. Only by employing a few workers, you can keep the running of the whole system.

What is the design of stirring teeth granulation system

In stirring teeth granulation process, it is advisable to use groove type compost turner, dynamic batching machine, SXSLF-800 new type vertical crusher, double shafts horizontal mixer, stirring teeth granulation equipment, polishing machine, SXGS-2080 rotary screener, SXHG-1540 rotary dryer, SXLQ-1540 rotary cooler, BM1600×6000 coating machine, automatic packaging equipment and so on.

| Equipment | Capacity (T/H) | Feeding Moisture | Granule Size (mm) | Pellet Shape |

|---|---|---|---|---|

| Stirring Teeth Granulator | 1-8 | 20%-40% | 2-5 | Round ball |

Can we set up a large scale organic fertilizer preparation system with 8-20 t/h?

Provided you plan to enlarge your organic fertilizer making business, you may need a rotary drum granulation system. Generally, it can help you prepare 8-20 tons, even 30 tons of organic waste fertilizer per hour. That is 50,000-180,000 tons of organic fertilizer pellets making a year. In addition, it has a higher performance on corrosion resistance, energy consumption reduction, automation, etc. So it earns the trust of large organic fertilizer production businesses at home and abroad.

How is the configuration of rotary drum granulation system

For large scale organic fertilizer making, you need to purchase equipment with large output. So our rotary drum granulation line usually contains wheel type compost turner, dynamic batching machine, SXSLF-1000 new type vertical crusher, SXWJ-1630 horizontal mixer, SXZYZ-2080 rotary drum pellet making machine, SXGS-2080 rotary screener, SXHG-2424 rotary dryer, SXLQ-2424 rotary cooler, BM1600×6000 coating machine, automatic packaging equipment and so on.

| Equipment | Capacity (T/H) | Feeding Moisture | Granule Size (mm) | Pellet Shape |

|---|---|---|---|---|

| Rotary drum granulator | 1-30 | 20%-40% | 3-6 | Round ball |

How much does the organic fertilizer making system cost?

For a complete organic fertilizer production line cost, it is closed related to the system design and capacity. Therefore, the quote of powder organic fertilizer making line is more favourable than the granulation. The price of 20 TPH organic fertilizer making system machines is higer than the 10 t/h. There are cost detailed of the standard layout from YUSHUNXIN for your reference.

Besides the above business plans for organic fertilizer production projects, we also have solutions to different materials. For example, chicken manure fertilizer making line, cow dung fertilizer production system, pig manure fertilizer manufacturing plan, etc. Therefore, you definitely can find the right design for your organic fertilizer manufacturing plant!