On October 22, 2025, a customer from Malaysia inquired about the practical solution to a $200,000 cost NPK Fertilizer mixing plant. “We need to mix materials like Mop, Ammonium Sulphate, P2O5, B, Cu… to produce NPK fertilizer. Minimum quantity need 250,000 MT annually. we are working 2 shifts per day each shift working 8 hours.” Finally, a 40TPH bulk blend fertilizer system is favored by the Malaysian compound fertilizer manufacturer. The following are the specific details of communication in this case:

How to produce NPK fertilizer of 250,000 MT annually with $200,000 cost?

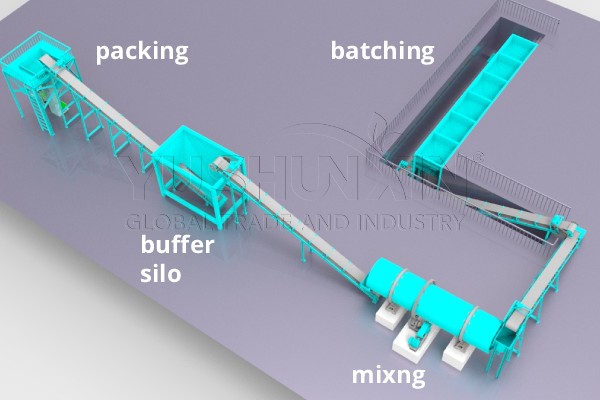

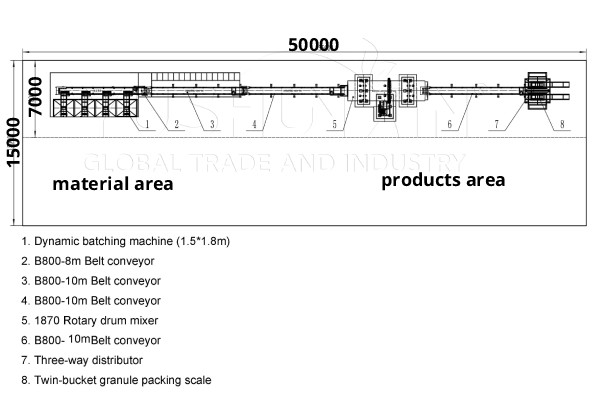

With an $200,000 cost, the fertilizer manufacturer from Malaysia hoped the annual capacity of the NPK fertilizer plant can reach to 250,000 MT. For this, a 40TPH NPK fertilizer blending system is your best operation.

How does the NPK Fertilizer mixing plant work to calibrate the proportion to 15-15-15 and 12-12-17?

At the same time, the Malaysian NPK fertilizer equipment buyer paid more attention of the calibration process of N, P, K pellets mixing. Because, he planed to prepare fertilizer of both NPK 15-15-15 and NPK 12-12-17. For this, a dynamic batching machine from YUSHUNXIN will fully meet your requirements. Because we especially design it with variable frequency conveyor with PLC controller, and electronic weight with ±0.2% precision.

Can we set up the $200,000 cost NPK Fertilizer mixing plant in an 800㎡ workshop in Malaysia?

The above are details about our communication with the customer about $200,000 cost NPK Fertilizer mixing plant in Malaysia. Besides, there also $100,000 NPK fertilizer business plans, $300,000 NPK fertilizer granulation line and $500,000 NPK fertilizer plant layouts for you choice. Come to get the best one now!