On 16th February 2025, a customer from Iran inquired about new carbon black granulation plant setup. He required a I am seeking a system capable of pelletizing carbon black with drying first. At the same time, it can create uniform, dust-free 3 mm pellets suitable for industrial applications. For this, we recommend him the roller press granulation line with 5 T/H capacity. The following are the specific details of our communication in this case:

What is the layout of a 30000 annual carbon black granulation plant?

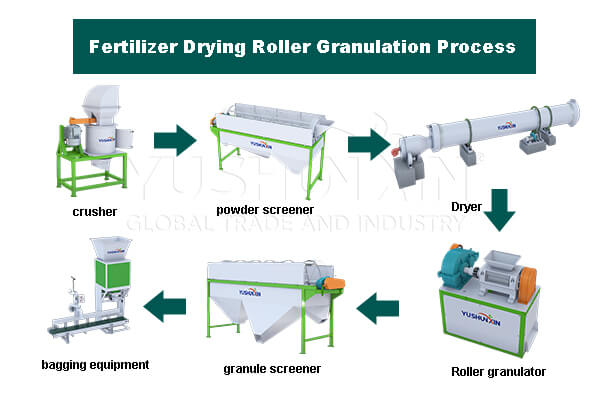

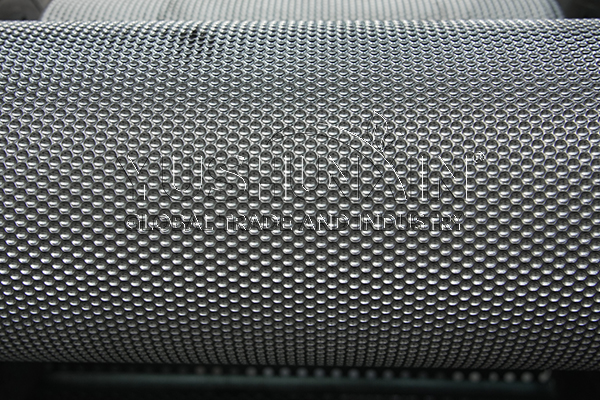

The Iran carbon black pellet manufacturer required drying before granulation. So, the layout of a standard 30,000 t/y carbon black granulation plant adopt double roller granulation system. The main carbon black granulation process flow contains 5 parts. Carbon black powder making→ rotary dryer → double roller extrusion granulator → rotary screener → packaging machine. In this setup,

Additionally, there are also supporting equipment such as conveyors, dust collectors, and a control system integrate the whole carbon black granules making line.

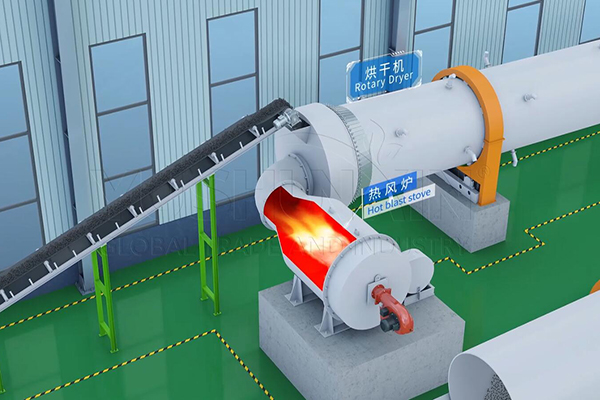

Can the rotary dryer dry carbon black to 5% moisture?

Yes, the rotary drum dryer is designed to bring down the moisture from about 30% to nearly 5%.

How about dust reduce in carbon black drying?

For one thing, the rotary dryer works in a closed drum, which greatly prevent carbon black powder disperse. For another, there is professional dust collecting system for carbon black drying. It contains both cyclone collector and water curtain filter for you.

How long does it take to get back the carbon black granulation plant investment?

When you estimate the time of a black carbon pellet making plant, you need to know the equipment cost. Buy it for YUSHUNXIN, The investment for a 30,000 annual ton carbon black granulation plant is about EXW $250,000. The details are as follows:

| Equipment | Capacity (t/h) | Power | Quantity | Quote |

|---|---|---|---|---|

| Carbon black crusher | 4-6 | 15 | 2 | $15,000 |

| Rotary drying system | 4-6 | 15 | $64,500 | |

| Roller press granulator | 2.5-3 | 22 | 2 | $60,000 |

| Rotary creener | 5-8 | 5.5 | 2 | $11,600 |

| Single packing machine | 4-6 bag/min | 1 | $18,000 | |

| Dust collector | cyclone, water and fan | 3 | $9,600 | |

| Belt conveyor | 10,12 m | 6-8 | $16,000 | |

| PLC controller | 1 | $8,000 | ||

| Total (EXW) | $202,700 |

With raw material sourced locally, production costs stay near $250–300 per ton. Market selling prices average between $400–600 per ton, giving a margin of $120–250. At full capacity, annual net profit can reach $3.6–7.5 million. However, during carbon black granulation plant opetation, there are also expense on area, energy consumption, labor force, etc. Therefore, the payback period is often only 1–2 years, which makes the carbon black granulation plant not just a production solution but also a highly profitable investment opportunity.

The above are details about our communication with the customer about 30000 annual carbon black granulation plant. Also, we also provide you with compost granulation plan, SSP pellet making system, NPK granule production solutions, etc for you. Welcome to get your own fertilizer business plan now!