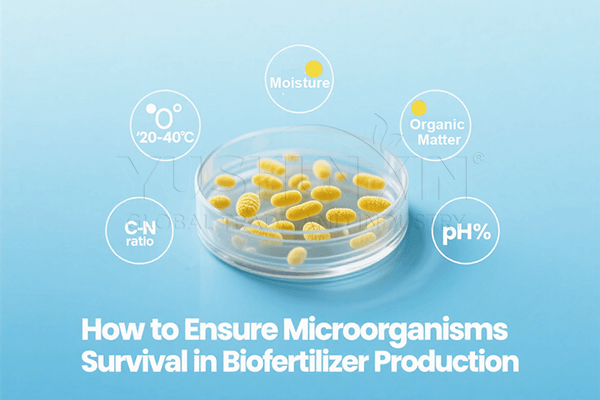

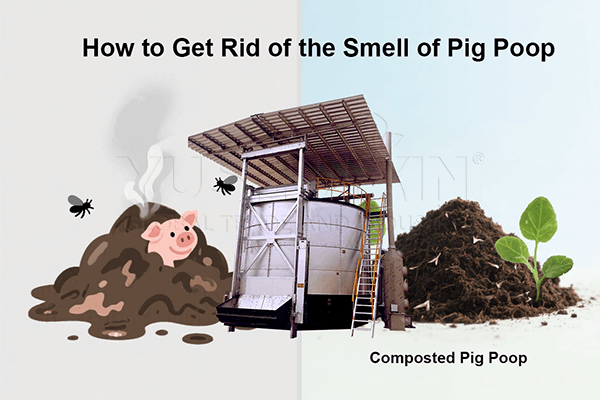

In general, the microorganisms survival in biofertilizer production is the most critical factor affecting the final product’s quality and efficiency. Since beneficial microbes are sensitive to environmental changes, producers must maintain optimal conditions during every stage. By managing temperature, moisture, organic matter, and pH, manufacturers can significantly improve microbial viability.

Why control the temperature for biofertilizer making to 20–40 °C?

Temperature directly affects microbial metabolism and enzyme activity. If it is too high, functional bacteria may be destroyed, and if it is too low, growth slows down. So, you need to control the temperature in bio fertilizer production between 20 ℃ and to 40 ℃. There are 2 tips for you.

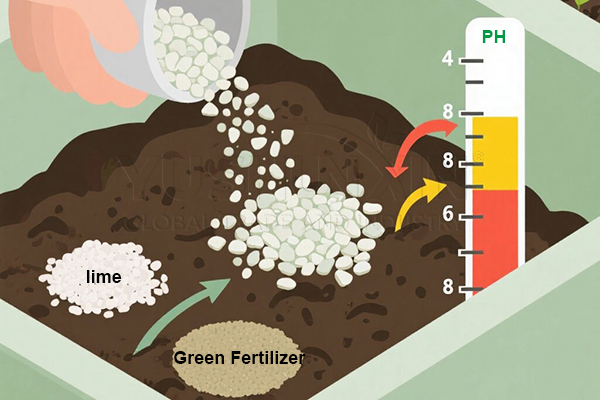

Ultimately, the microorganisms survival in biofertilizer production depends on precise environmental management. By controlling temperature, regulating moisture, maintaining proper organic matter content, and adjusting pH to suit specific functional microbes, you can deliver biofertilizers with high microbial counts, long shelf life, and reliable agricultural benefits.