Compared to other NPK fertilizer making plans, BB fertilizer system requires a simpler process and less land. So, many fertilizer manufacturers prone to the NPK granules blending plan. But, is there detailed information about a 20 T/H BB fertilizer system land required? Of course. Based on a standard bulk blending fertilizer equipment configuration and workflow design, it is only 400-600㎡.

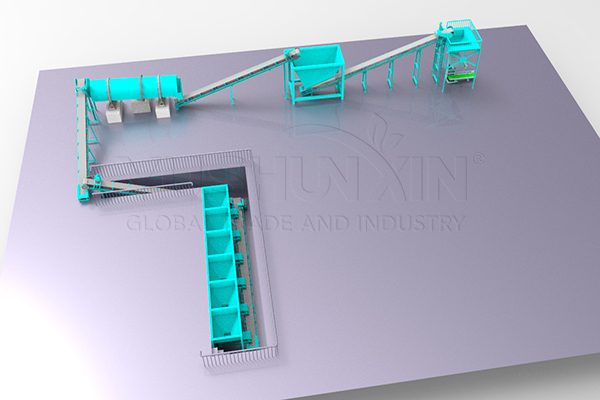

What is the Equipment Layout of a 20 T/H BB Fertilizer System?

For a 20 T/H BB fertilizer making line, it only need 4 machines as follows.

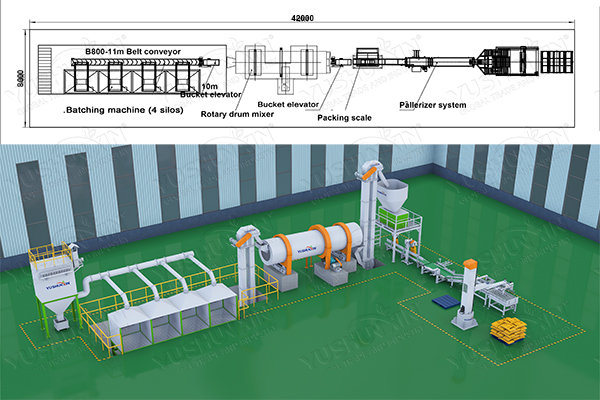

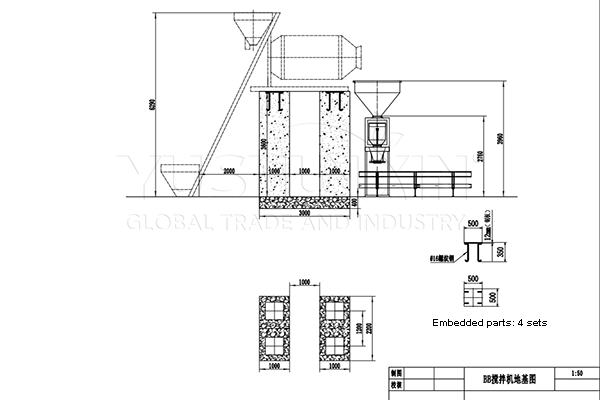

Dynamic Batching Machine

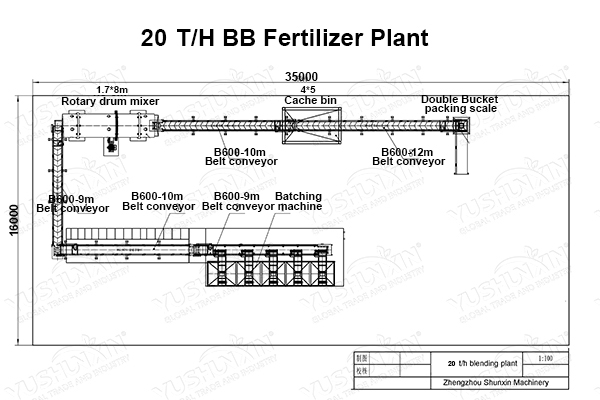

The production process begins with a multi-hopper batching system that allows for simultaneous handling of 2-6 types of raw materials. This section is usually positioned at the head of the line to facilitate granule material input strictly with required proportions. Usually, this occupies a significant footprint. Every hopper can be 1.8*2.5 m.

1.7*8m Rotary Drum Granules Mixer

As the heart of the BB fertilizer making process, granules mixer ensures a uniform blend of all materials. For a 20 t/h output, the 1.7*8m rotary drum blender is the best choice for you. With drum shape design, it can mixing 20 tons of N,P, K fertilizer granules evenly quickly by rotation.

4*5m Cache Bin

The cache bin provides a buffer zone between fertilizer granules mixing and blended NPK fertilizer packaging, ensuring the process remains uninterrupted. It also allows for short-term storage of mixed fertilizer before final weighing. For a 20 t/h BB fertilizer system, it need a 4*5m cache bin.

Double Bucket Packing Scale

At the end of the 20 t/h BB fertilizer production line is the packaging system. The dual bucket packing scale is used to weigh, fill bags and sealing of mixed fertilizer in a large scale efficiently. In general, you need only to prepare 2 workers for the process.

Series of Belt Conveyors

Belt conveyors are key to transporting raw materials through each processing stage. Usually, a 20 t/h NPK granule mixing plant uses 3-5 sets of B600 conveyors with varying lengths (9m to 12m) strategically placed between equipment, ensuring smooth, continuous material flow. These conveyors are installed in sequence to minimize turning and space consumption.

With this design, you need to prepare a 500-600 ㎡ area for your 20 t/h fertilizer granules mixing plant. For example, a workshop of 16*35 m.

Can we set up a 20 T/H BB fertilizer system on a 400㎡land?

To install a fully functional 20 T/H BB fertilizer making line with the above configuration, a land area of 400-600㎡is sufficient. If you want to learn more about bulk blending fertilizer making line or other fertilizer making solutions, welcome to contact us now! There also are NPK granulation plan, phosphate rock fertilizer production plan, manure fertilizer making system, etc for you!