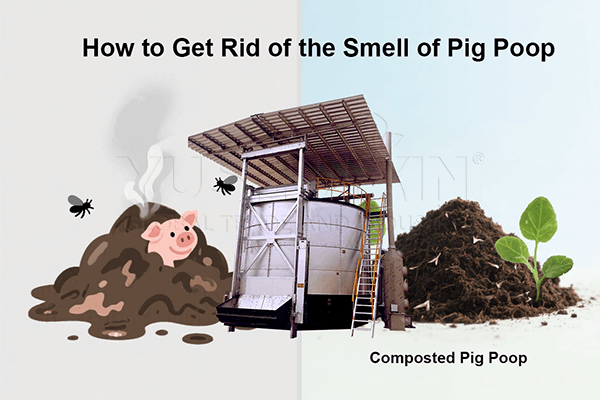

In the production of fertilizer granules, binders adding can help you produce granular fertilizer with better strength, durability, and cohesion. However, many producers overlook the correct granular fertilizer binders adding method and timing.Which is key to ensure the final effect. For this, there are 3 methods for your choice. Mixing, granulation and coating. You can choose the best one according to your purposes, fertilizer types, granulator using, binder shape, etc. Here, YUSHUNXIN will offer you customized fertilizer making solutions and equipment.

Top 3 Methods to add granular fertilizer binders

In the process of fertilizer pellet making, you can add suitable binders in 3 stages: mixing, granulation or coating.

Mixing with binders for fertilizer granule making

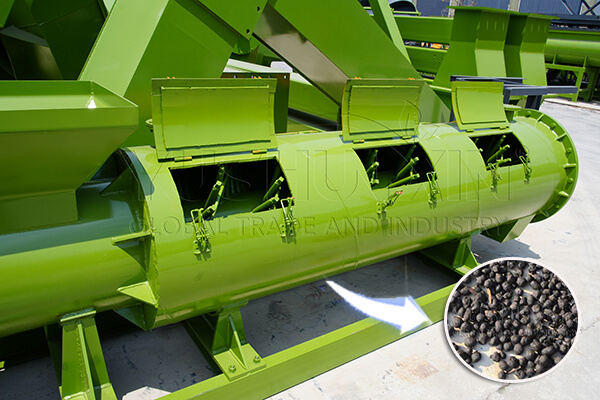

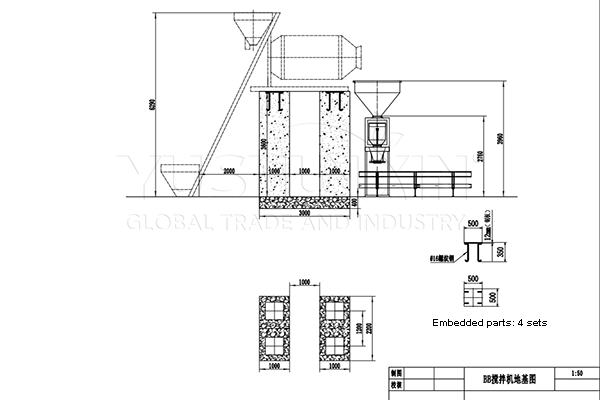

In this process, you will mix compost or chemical powder with the granular fertilizer binders evenly. In this way, the additives can fully play it role of improving cohesion and strength. For this, the double shaft horizontal mixer is an ideal choice. It has professional binders adding system for both powder and liquid while work continuously.

Adding binders during granulation process

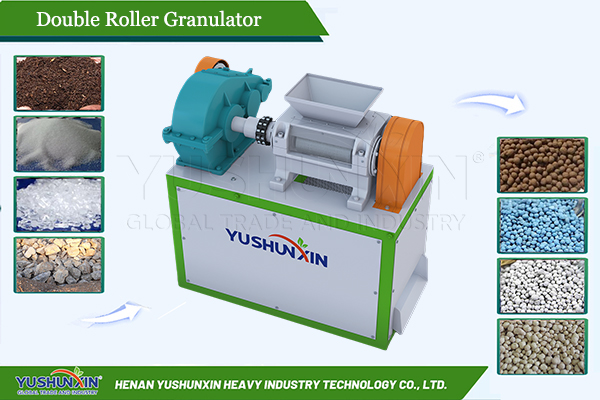

If you want to add fertilizer binders during granule making directly, there are also customized fertilizer pelletizers for you. Whether you want to buy a pan pellet machine and rotary drum granulator, YUSHUNXIN can offer you them with spray device.

Coating granulated fertilizer with binders

In addition, you also can choose to feeding additives after granulation by coating. For heat sensitive material adding, this is the best way to prevent damage. Here is also rotary coating machines with professional feeding systems of powder and liquid for you.

How chose the best granular fertilizer binders adding method?

When choosing a binder adding method for fertilizer granulation, several factors must be taken into account:

Your purpose: Improving fertilizer ball strength or speeding up the powder to granules process?

Before choosing granular fertilizer binders, you need to clear your purpose in fertilizer pellet making. Improving fertilizer ball strength or speeding up the powder to granules process?

Can we add powder binders for fertilizer pellet production?

Of course. Whether you want to add liquid or powder binders for granular fertilizer manufacturing, there are customized systems for you. For the liquid feeding, there are special spray system. It can help you control the binder adding volume precisely. Moreover, there is also screw type conveyor for powder additives feeding. The machine can transport powder materials more precisely and less dust.

What granular fertilizer binders are commonly used?

As mentioned above, there are 5 types of binders are commonly used in fertilizer pellets manufacturing.

Starch to speed up fertilizer pellet making

Source: Corn, potato, or tapioca.

Function: A natural binder that helps improve granule strength and cohesion. It is biodegradable, making it a good choice for organic fertilizers. Starch is most effective when the granulation process involves slightly moist conditions.

Cellulose as granular fertilizer binder

Source: Plant fibers.

Function: A natural binder that works well in creating durable granules, especially in organic or bio-based fertilizers. Cellulose helps retain moisture and improves the overall strength of the granules.

Polyvinyl Alcohol (PVA) for NPK fertilizer granulation

Source: Synthetic polymer.

Function: PVA is highly effective in creating strong, water-soluble granules. It is often used in NPK fertilizers or other synthetic fertilizer blends. PVA offers excellent moisture resistance and durability.

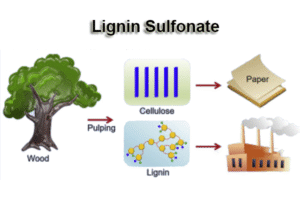

Lignin Sulfonate as binder for fertilizer granulation

Source: Byproduct of the paper industry.

Function: An environmentally friendly binder that offers a high level of adhesion. It’s often used in combination with NPK and other compound fertilizers to improve granule strength at a lower cost.

Resin for fertilizer granulation better

Source: Synthetic materials. e.g., Phenolic Resins

Function: Resins are used to produce granules with high strength and resistance to moisture. They are ideal for fertilizers that require mechanical stress resistance, such as high-density NPK fertilizers.

If you have any other things want to know about fertilizer granulation or fertilizer preparing, welcome to contact us immediately.