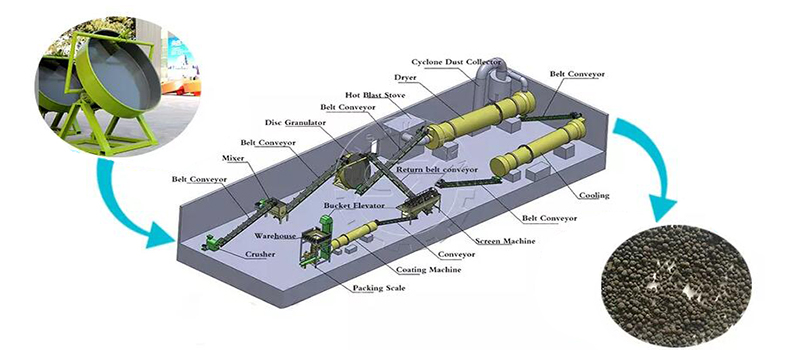

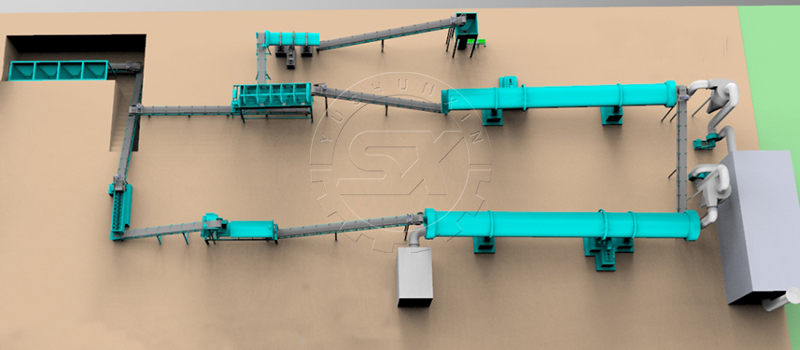

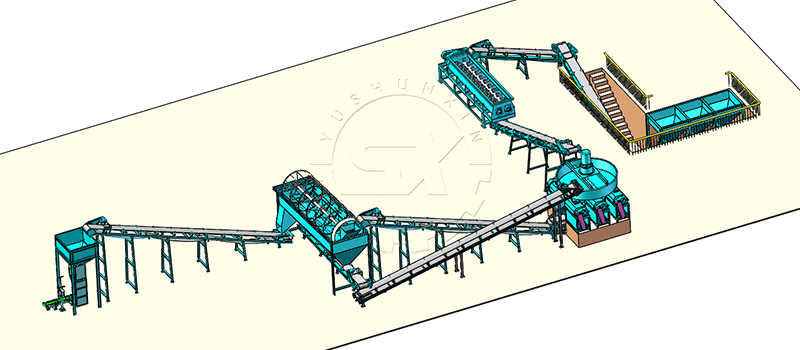

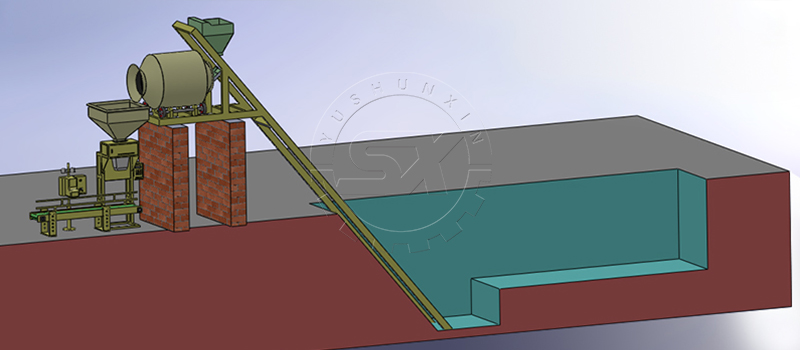

When you want to setup a NPK fertilizer plant commercially, a reasonable design is important. It not only can make your NPK fertilizer production more smoothly but also is beneficial for reducing the cost of NPK compound fertilizer production. Here, SX fertilizer equipment factory can help you a lot. We provide you with area division, NPK fertilizer production line drawing, suitable equipment, required area, etc. In addition, if you have any other requirements about NPK fertilizer plant design, you also can contact us for solutions.

How many areas does a NPK fertilizer making factory cover?

Besides NPK fertilizer function area division, it is dispensable to know the area coverage in NPK fertilizer plant design. Then both material area and final fertilizer area are related to output simply. The smaller the capacity, the smaller the area needed. However, for the occupation area of NPK fertilizer production line, you also need to consider the method and equipment you choose.

What can SX do for your NPK fertilizer plant setup?

As your good partner, SX can provide you with suitable equipment for the whole process of NPK fertilizer manufacturing. We will offer you NPK fertilizer plant design according to your actual conditions and requirements of material, capacity, area, equipment, etc.